Sukup Manufacturing Co. products

Grain Bins

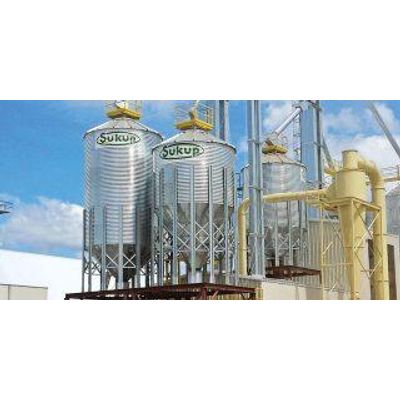

Sukup - Heavy Duty Hopper Bins

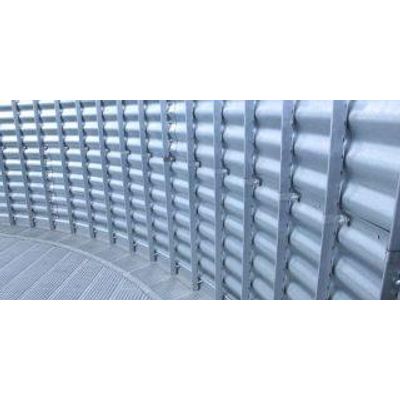

The Heavy-Duty Hopper Bin is a robust and versatile grain storage solution. Heavy-Duty Hopper Bins may be mounted on overhead superstructures, making it an ideal choice for efficiently loading semis or train cars. The design of Sukup Heavy-Duty Hopper Bottom Bins is among the strongest in the industry, with wide corrugations, extra-strong stiffeners, and heavy-duty hopper panels.

Sukup - Medium Duty Hopper Bins

Sukup Medium Duty Hopper Bins are engineered for smaller-scale operations, offering an economical yet robust solution for grain storage. These hopper bins are designed to serve multiple purposes in your grain handling system. They are an ideal choice for use as a wet holding tank, directly feeding your Sukup grain dryer with efficiency. Additionally, these bins are suited for the extended storage of cool, dry grain, ensuring your grain remains in optimal condition over time.

Grain Dryers

Sukup - Centrifugal Grain Dryers

Sukup Centrifugal Dryers are available as full-heat only models or as pressure-heat/vacuum-cool models. The full-heat models operate the same as Single Axial Fan dryers except that centrifugal fans run more quietly. Pressure heat/vacuum-cool dryers can dry in heat/cool mode and operate nearly as efficiently as a full-heat dryer. Pressure heat/vacuum-cool dryers have a 2/3-1/3 split plenum allowing the centrifugal fan to create a vacuum in the lower plenum of the dryer and pull outside air in through the grain column. This cools the grain and heats the air, which is then fed into the intake of the fan. The warmer air coming into the fan and heater then reduces the amount of gas needed to dry within the upper plenum.

Sukup - Full-Heat Mixed-Flow Grain Dryer

The Sukup Full-Heat Mixed-Flow Dryer is engineered to enhance the grain drying process, optimizing both capacity and quality. Unlike traditional cross-flow full-heat dryers, this unit features wide 30-inch grain columns that accommodate more grain in process compared to 14” or narrower cross-flow columns. While holding more bushels, the grain is dried slowly and only uses about half the airflow per bushel. Since full-heat dryers only heat the grain, the grain is cooled over 24-48 hours in a grain bin, lowering the potential for stress cracks in the kernels and promoting better grain quality.

Sukup - Mixed-Flow Grain Dryer

The Sukup Mixed-Flow Dryer (U.S. Patent #10,378,820) is the only one on the market that combines the excellent grain quality of a mixed-flow dryer with the vacuum-cooling efficiency of a tower dryer. The result is high test-weight grain while burning less fuel per bushel dried. Maintenance is also reduced with mixed-flow dryers because there are no screens that need to be cleaned on cool, damp days to maintain capacity and efficiency.

Grain Handling

Sukup - Air Tube Systems for Grain Aeration

Sukup Airways Air Tube systems are designed to significantly enhance the efficiency and effectiveness of grain aeration during grain storage. Recognizing the importance of proper aeration in grain handling and storage, these systems are developed to maintain the quality and longevity of stored grain by working to remove the water from the wall.

Sukup - Axial Fans and Heaters for Grain Quality

Sukup`s Axial Fans and Heaters are engineered to provide efficient, reliable airflow and even heat distribution for maintaining grain quality.

Grain Handling Equipment

Sukup - Double Run Grain Conveyor

The Sukup Double Run Conveyor is an efficient grain handling system designed to reduce grain damage while maximizing throughput and is more economical and effective than portable augers. Sukup`s Double Run Conveyor is engineered for gentle and efficient grain movement, replacing the need for a roof auger, transfer auger, dryer take-away auger, and even a permanently installed transport auger. With its compact design, the Double Run Conveyor operates smoothly and quietly, requiring minimal maintenance. The Double Run Conveyor features 100% UHMW paddles pre-attached to the chain.