Symaga products

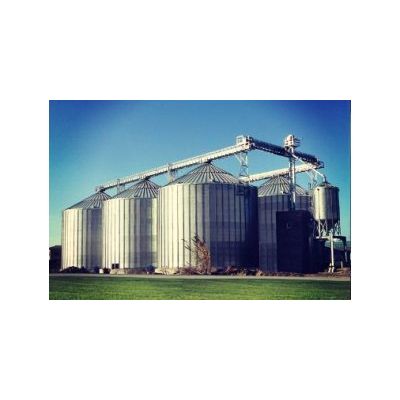

Symaga - Flat Bottom Silos

Our metal flat and conical bottom silos are the most efficient solution for long-term storage of large volumes of grain. Our wide range of models and accessories can be applied to many different industries such as malting plants, feed mills, port terminals, mills, bioethanol plants, dryers, flour mills, and the plastic and biomass industry.

Symaga - Hopper Silos

Our metal hopper silos are the optimal choice for storage and the unloading of grain by gravity. Essential in sectors such as breweries, feed mills, port terminals, mills, bioethanol, oilseeds, dryers, flour mills, as well as storage of raw material for the plastic and biofuel industry.

Symaga - Delivery Silos

Symaga provides delivery Silos that are used to unload grain into trucks or trains. These silos, designed for daily storage, facilitate the trasnfering of grain from high capacity silos to delivery silos, to be placed in the container.

Symaga - Mass Discharge Silos for Efficient Grain Storage

Mass discharge silos are engineered to enable all contents to be in motion simultaneously, crucial when handling granular products like grain. This design is paramount for companies seeking efficient and uniform discharge systems, minimizing product stagnation at silo bottoms. However, the simultaneous movement generates increased lateral pressures, necessitating robust construction to withstand these forces. Compliant with EUROCODE 1.4 -4, these silos are designed considering eccentric discharge calculations that address and mitigate potential structural stress points. The silos are made with guaranteed steel types: S450 GD and specialized coatings like Z600g/m² on the cylinders and ZM310g/m² on the roofs to enhance durability against environmental conditions. Diameters range from 4.60m to 32.08m, and they have capacities from 83 m³ to 25,000 m³. Specific design features include trapezoidal and omega profiles for improved rigidity, technical sheets available for most components, and a focus on maximum resistance and design efficiency.

Symaga - Feed Silos

Our feed silo for efficient feed storage in livestock facilities is optimised according to EUROCODIGO. Our technicians adapt the design and capacity of the silo and the feed distribution system to the required demand.

Symaga - Flex Auger Feed Delivery System

Economical and efficient solution for the transport of granular or mashed products for livestock or industrial sector where it is not necessary a big flow of production per hour and day.

Symaga - Chain Feed Delivery System

The Chain Feed Delivery System is designed to offer safe and versatile transport solutions for various types of animal feed, including granules, flours, pellets, and mixtures. This modular system is adaptable to any building design, with a key feature being its ability to change direction up to 90º to facilitate feed transport directly from the silo outlet. Compatible with a flex auger system, it accommodates a 60mm diameter metal tube. Various components such as silos, loading units, tubes, clamps, elbows, drive units, and control panels ensure efficient and secure feed handling. The drive unit includes a geared motor and safety systems to prevent malfunctions, while the control panel offers manual, automatic, and stop functionalities. Additionally, the system comes with adjustable outlets and dispensers to manage hopper or feeder capacities effectively.

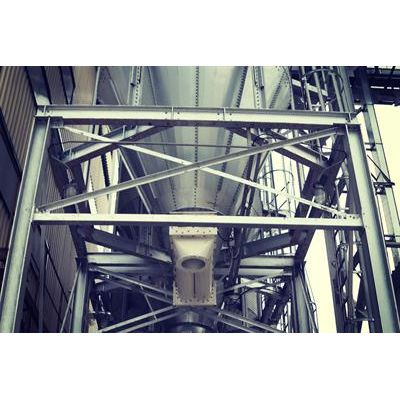

Symaga - Assembly Supervision for Symaga Silos

Symaga provides comprehensive assembly supervision services to enhance the efficiency and quality of silo installations globally. The assembly supervisor collaborates closely with the assembly team, providing instructions and guidance to expedite the assembly process while ensuring strict adherence to high-quality standards. An initial installation schedule is established to streamline workflow, and a weekly report is issued to monitor progress meticulously. The dedicated team of instructors coordinates the installation process to prevent any delays, ensuring timely execution of storage projects worldwide. Symaga's assembly supervision is committed to precision, offering detailed planning and reporting to meet diverse project requirements effectively. The technical expertise and global reach ensure seamless execution of storage solutions, adding value to every project undertaken.