TTA-ISO products

ISO - High Speed Clipper for Industrial Use

The ISO High Speed Clipper is engineered to meet the rigorous demands of industrial environments. It features advanced technology aimed at enhancing efficiency and precision in production cycles. This machine is particularly suited for industries that require fast and reliable clipping solutions, reflecting ISO's commitment to quality and innovation. Designed with user accessibility in mind, the clipper ensures ease of operation while maintaining high standards of safety. Capable of integrating seamlessly into existing production lines, it provides businesses with the ability to increase throughput without sacrificing quality. With a focus on durability, the ISO High Speed Clipper is constructed from high-grade materials that withstand intense use, ensuring longevity and reliable performance.

ISO - Automated Tomato Harvesting Robot for Greenhouses

ISO Horti Innovators presents the ISO Harvesting Robot, an innovative solution designed to address the labor-intensive process of tomato harvesting in greenhouses. This advanced machine integrates deep learning AI technology to accurately assess and select tomatoes, mirroring the precision found with human hands. The robot automates the entire process from cutting to harvesting, significantly enhancing efficiency and reducing costs associated with manual labor. Equipped with self-learning Vision AI and patented cutting technology, the ISO Harvesting Robot achieves high accuracy in selecting ripe tomato clusters, ensuring optimal harvest quality. Its high capacity and short cycle times contribute to increased harvesting speed, offering a rapid return on investment. The system also includes an innovative disinfection function to minimize disease spread, supporting hygienic operations. With the ability to manage multiple machines simultaneously, operators can optimize workflows and respond to market demands swiftly, making it an essential tool for the modern agricultural landscape.ISO - High Speed Grafter - Automated Plant Grafting Machine

The ISO High Speed Grafter represents a significant technological advancement in the horticulture industry as the first fully automated grafting machine. Designed to address labor shortages and enhance grafting precision, this machine can graft up to 4,000 plants per hour using advanced Vision AI technology and robotic systems. The machine autonomously manages the grafting process, from selecting eligible rootstocks and scions to completing the graft and quality inspection. This level of automation reduces the need for intensive manual labor while ensuring consistent, high-quality grafts that improve plant resilience and growth. The Grafter's AI system is self-learning, adapting to different crops, making it versatile enough for use in diverse agricultural applications, such as tomatoes and potentially peppers and trees. It is operator-friendly, requiring minimal human oversight, which translates into significant labor cost savings. Developed in collaboration with growers, the ISO High Speed Grafter ensures reliable and uniform output, forming the backbone of robust and resistant crops.

ISO - Automatic Cutting Planter Robot for Efficient Horticulture

The ISO Cutting Planter robot revolutionizes the initial cultivation process with its ability to plant cuttings uniformly, rapidly, and accurately using a combination of vision technology and artificial intelligence. Designed to work with various pot and tray formats, this machine eliminates the need for manual selection of cuttings and improves efficiency with planting speeds reaching up to 2,800 cuttings per hour. It features an adjustable design for different crops and planting patterns, making it versatile for a wide range of horticultural applications. The integration of self-learning vision software and a vibrating conveyor belt ensures precise planting depth and separation of plant material. The ISO Cutting Planter also employs advanced gripper technology for damage-free planting, enhancing root development and minimizing stem breakage. Its user-friendly operation allows a single operator to manage up to seven machines, significantly cutting labor costs while boosting productivity and process continuity.

Transplanting Plugs

TTA-ISO - Robot Plug Planter

The Robot Plug Planter, offered by TTA-ISO, is an advanced automated solution specifically crafted for the efficient planting of chrysanthemums. This device enhances root development by placing a soil plug instead of traditional press pots. Soil plugs, being more natural and peat-free, facilitate quicker and healthier root establishment compared to press pots. The planter ensures minimum root disturbance, accelerating plant establishment for a robust start, and a shorter growth cycle. This results in higher yields per area and improves the proportion of A-quality flowers. It also reduces susceptibility to root diseases such as Pythium, thus lessening or negating the necessity for pesticides. The Robot Plug Planter boasts an impressive capacity of up to 18,000 plugs per hour, making it a highly efficient tool for large-scale ornamental plant cultivation.

Germination Correction

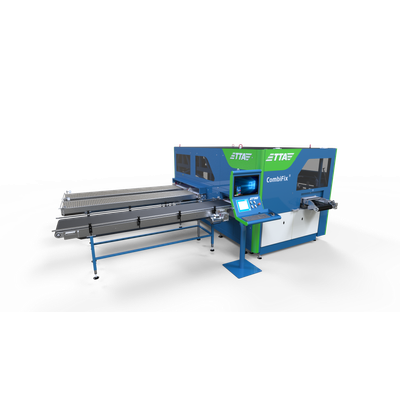

TTA-ISO CombiFix - Plant Tray Filling and Correction Machine

CombiFix is an advanced automated machine designed for efficiently correcting plant trays to achieve 100% occupancy with qualified plants. This system targets young plant trays, optimizing space and ensuring uniformity, which is crucial for automated transplanting processes. With its in-house imaging system, CombiFix evaluates each plant's optical appearance, identifying and removing empty plugs or substandard plants through a sophisticated blow-out mechanism. The machine incorporates a direct magnetic drive system for the plant gripper, ensuring rapid movement and precise positioning, thereby reducing maintenance over time. Additionally, the TTA-ISO's pusherpin technology allows even fragile plants with minimal root structures to be handled delicately. CombiFix supports sustainable operations by maximizing space efficiency and enhancing plant developmental consistency. Its compact size of 3.8 x 2.2 meters streamlines operations, supported by destacking units and discard rollers. Capable of processing between 12,000 to 20,000 plugs per hour, CombiFix sets a benchmark in automation for horticultural industries.

Transplanting Cuttings

TTA-ISO - Single Cutting Planter

The CuttingEdge Single is an advanced automated system designed for the precise and efficient planting of both rooted and unrooted plant cuttings. This machine revolutionizes nursery operations by significantly enhancing the planting process. It achieves high precision and productivity with the capability to handle between 1,800 and 2,500 cuttings per hour. The machine features a chain conveyor system that aligns plug trays accurately at their destination. Cuttings can be sorted manually or using the VisionAir system, which employs cutting-edge vision technology paired with air jets to meticulously separate and assess each cutting via the TTA-ISO CuttingVision system. Only qualified specimens are placed in the trays by a robotic arm, with rejected or redundant cuttings rerouted back to the operator. Additionally, users can leverage VisionHub's centralized data to optimize cutting setups, facilitating robust, time-efficient processes. The system's flexible design allows multiple machines to be networked together, scaling up capacity based on specific nursery needs.Sorting

TTA-ISO FlexSorter - Advanced Plant Sorting and Transplanting System

The FlexSorter by TTA-ISO represents a sophisticated solution for horticultural sorting equipment, melding transplanting and plant grading in a singular process. Utilizing proprietary plant grippers and supported by a pusher pin system, the FlexSorter efficiently extracts plants from donor trays. A key feature of this machinery is its ability to handle plugs only once, drastically reducing potential damage from multiple handling. The FlexSorter uses an imaging system with an intuitive interface and integrated self-diagnosis to streamline operations. Capable of managing 3,000 to 12,000 plugs per hour, this equipment excels in high-capacity environments. The system supports a maximum of four classifications, directing approved plants to corresponding destination belts while rejected ones are gathered on a waste belt. Suited for use in nurseries, the FlexSorter optimizes efficiency with reduced manual intervention, marking it as a significant advancement in plant sorting and transplanting technology.

Grafting

TTA-ISO - Fully Automated High-Speed Grafting Machine

The TTA-ISO High-Speed Grafter represents a significant advancement in the domain of automated horticulture. It is engineered to graft plants with a precision that surpasses traditional manual methods, by utilizing advanced Vision AI technology. This fully automated machine has the capability of processing up to 4,000 plants per hour, ensuring consistent quality and improved yield. The process involves the automated feeding of rootstocks and scions, which are meticulously inspected via cameras for parameters such as size, height, and stem integrity. Only adequately checked plants are grafted using a lightweight clip, followed by a final quality scan, eliminating the variability of manual grafting. This innovative technology replaces human error with machine precision, enhancing both the grafting accuracy and the resilience of the plants produced.