UNI-MASZ H.M.Juszczuk Sp.j. products

Strawberry Machinery

UNI-MASZ - Horizontal Screw Blancher Unit

HORIZONTAL SCREW BLANCHER – Unit for fast process using high temperature for vegetables, mushrooms to inactivate oxidized enzymes, preserve color, dispense airborne microbes, increase taste values and digestibility. After blanching it is advisable to cool down quickly (additional unit) to acquire product temperature which is suitable for further technological process ex. freezing. Unit made in shape of horizontal pipe with rotating perforated screw that is immersed in the water (total volume of the pipe is used for the process). Injection of steam direct into the water. Blanching time is regulated by rotation speed of the screw. Water temperature T=960C controlled by the control/regulation device. An even charge of the product is required. Product output is realized by the rotating bucket installed directly to the main screw shaft. Made from the stainless steel AISI 304

UNI-MASZ - Skew Screw Blancher Unit

SKEW SCREW BLANCHER - Unit used for blanching vegetables, mushrooms. After blanching it is advisable to cool down quickly (additional unit with cold water sprinklers in skew screw output section) to acquire the product temperature suitable for the further technological process ex. freezing. Unit made in shape of the skew pipe with the rotating screw inside immersed partly in water. (Water level inside the channel is set by charge basket height and pipe lean angle). Injection of steam is direct into the water. Blanching time is regulated by rotation speed of the screw. Water temperature T=96oC which is controlled by control/regulation device. Even charge of the product is required. Product output directly from screw pipe. Made from the stainless steel AISI 304.

Strawberry Potato, Carrots, Beet Machinery

UNI-MASZ - Rotary Table

Rotary table as a products buffer. The product e.g. in the form of small packages of fresh vegetables for the purpose of further packaging or storage in the larger containers accordingly to the table - rotates with the disc. Employees receive handmade product for further processing or packaging operations. Power feed of a rotating disc centrally underneath - by motoreductor.. Depending on the diameter of the table (pictured disc Φ 3 m, for manual packaging broccoli in trays, electric sockets on the sides to work with hand tools) resting on one leg or more central support roller or rollers along the circumference

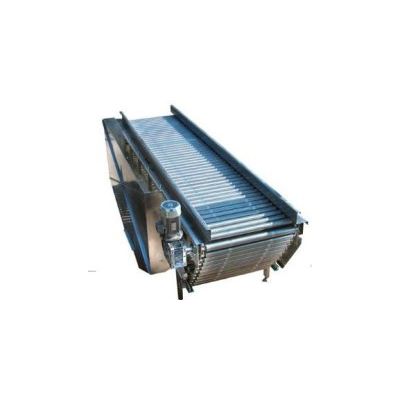

UNI-MASZ - Roller Inspection Table

The device is designed for the inspection-sorting of the round shaped raw material (potato, beet, onion, carrot, cucumber, etc.). Set of the rotating rollers rolling on the treadmill. The rollers associated with the chain on both sides. Gear wheels drive the chains - pulling them, and thus the rollers which roll on the lower raceway, to rotate. On the edges along the sides there is a gap for the waste. Wastes fall into the pull-out drawer (between the rolls), or to a tank under the table. The used water sprays rinse raw material and wash out the impurities from the rollers and channels for disposal. Power feed by motor eductor with the inverter for the infinitely variable speed adjustment of the tape.

UNI-MASZ - Accumulation(Buffer) Rotary Table

Rotary table as a products buffer. The product e.g. in the form of small packages of fresh vegetables for the purpose of further packaging or storage in the larger containers accordingly to the table - rotates with the disc. Employees receive handmade product for further processing or packaging operations. Power feed of a rotating disc centrally underneath - by motoreductor.. Depending on the diameter of the table (pictured disc 4* 3 m, for manual packaging broccoli in trays, electric sockets on the sides to work with hand tools) resting on one leg or more central support roller or rollers along the circumference

Raspberry Machinery

UNI-MASZ - Raspberry Separator Air Cleaner with Elevator

Unit used to separate leafs and light pollutions from the fresh berries and other fruits in similar size before the washing process. Fruits are passing to elevator (slotted belt with low and thick arranged threshold) and then they are lifting up to the fan separator where they fall down and the pollutions from these products are lifted up and taken out.. Fruits without the impurities are falling down and on the slotted sieve and transported out. Light impurities are collected in the sacks.

Broccoli and Cauliflower Machine

UNI-MASZ - Belt Blancher Unit

The unit is used to the vegetables blanching and cooling using the outside air. Cooling occurs when the water evaporates from the product surface. Final temperature depends on the air temperature, we assume that the product temperature is higher by about 10 0C from the air blowing on the product in air cooling zone. To cool down the product additionally we can use the ice water +2 0C.

Plum Handling Machinery

UNI-MASZ - Size Fruit Grading Vibrator

Size Grading Vibrator used to sorting the frozen fruits and vegetables on the hole or slotted sieves which are interchangeable. Way of disposing layers (sieve under sieve/sieve after sieve) and their amount (1-4) and also size of the hole or gap to be agreed.

UNI-MASZ - Drum Fruit Sorting Machine

Drum sorting machine used to sorting the frozen fruits and vegetables on the hole sieves. Gauge number, sieve material (PCV/KO) and the hole size in sieve to be agreed.

UNI-MASZ - Roller Sorting Machine

ROLLER SORTING used to sorting frozen fruits and vegetables on rollers. Gauge number and gap between the rollers to be agreed.