Viscon Plant Technology products

Box Making Machines

Boxes come in different styles and dimensions and are often required to be formed automatically to supply high capacity processing lines. Viscon supplies box making machines for American boxes, self-carrying open boxes and display boxes. Depending on the type of box, the required capacity and application, Viscon can extend the system with e.g. automatic case packers, box closing machines, palletisers, etc.

Viscon - Model ViTrolley - Trolley

As a key part of your plant growth facility, our ViTrolleys have a unique design and are fully compatible with our ViCabins. The trolleys with diffused LED panels create the ideal light spectrum, climate, and day-night rhythm for your plants. This helps you achieve uniform, better quality plants and accelerates the cultivation process.

Case Packers

To pack goods into their final package, Viscon supplies various case-packers for a wide range of products. There are standard case-packers for packed product (that has been packed in stretch film, been flow-wrapped or lidded), case-packers for single products in a bag or net package and case-packers for bread and bakery products. Besides these standard case-packers there are also systems for block packaging and bigger final packages. Other products that are not mentioned can often be packed using our systems but please contact your Viscon specialist for advice.

Loading and Unloading Systems

For conveying products to and from the machines included in your automation project, Viscon supplies loading and unloading systems that can be adjusted to virtually any product. This often relates to the loading and unloading of trolleys and racks some examples of which are shown on these pages.

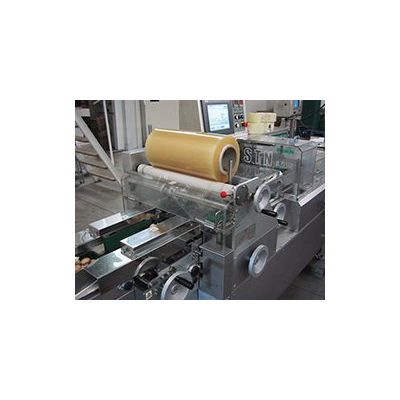

Packaging Machines

When packing for example bakery products, fruits, vegetables, meat and fish, Viscon supplies several types of packaging machines. To provide the correct type of product packaging, there is the choice of flow-wrappers, stretch film wrappers, ultrasonic welding machines and machinery for resealable lids. In addition to ‘’retail pack’’ machinery, Viscon also offers machinery for large and speciality pack requirements or for products of which it is impossible to be packed by the machinery mentioned above.

Palletising and De-Palletising Units

Viscon’s palletising and de-palletising units are able to process a large variety of products. There are for instance palletising and de-palletising units for boxes, crates, various types of trays and virtually any product of a rectangular design. The choice of the correct palletising and de-palletising unit depends on the capacity, stacking patterns, pallet formats and the stability of the product. These units can be integrated with pallet strapping or wrapping units. Depending on the product, the palletising and de-palletising units for crates and some boxes can be supplied as ‘semi’ or fully automatic models.

Stacking and De-Stacking Systems

Viscon’s stacking and de-stacking systems are available for a whole variety of uses. For example, stacking/de-stacking for crates and trays, wooden pallets, boxes, buckets, punnets, cardboard sheets, steel racks, pallet bins, vacuum and polystyrene trays. The type of machine required is determined by the product and by the capacity required. The machine can be manufactured in single or multiple formats to cope with product outputs of over 3000 products per hour.