Whatcom Manufacturing, Inc. products

Dairy Equipments

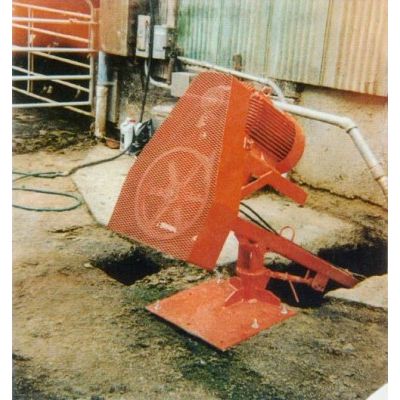

Whatcom - Prop Dairy Agitator

We have been producing quality built agitators for over 20 years, and our experience has helped us to build a durable, efficient machine. Agitators can be ordered in sizes from 35’ up to 50’ in length. Each agitator uses a large diameter slow speed propeller constructed of Hardox 500 steel plate. Each balanced for years of vibration free service. All bearings are grease lubed from 1 grease band at the front of the agitator. A Heavy Duty ball bearing at front, nylon sleeve bushings in the stem, and a bronze sleeve bearing at the back provide ample shaft support.

Whatcom - Sand Bedder

Whatcom Sand Bedders are a specially designed heavy duty bedder built to handle the extra wear and stress sand can do to a machine. Different sizes and have different options to accommodate every dairy’s needs. Works very well with sawdust, shavings, manure, solids, sand, ect…

Whatcom - Model WTSB - Slurry Splasher Plate

3 Splasher plate Model WTSB. 15’ wide. Heavy-Duty steel construction. Double swivel. 4” shutoff valve. Cat III quick hitch. Interchangeable nozzles.

Mulching Equipments

Whatcom - Model Y Series - Mulcher

WHATCOM MANUFACTURING’S New Y series mulch spreader wagons are specifically engineered for row mulching coverage with wood chips, bark or stringy compost mixtures. The Y shaped box gives increased capacity along with non-clog feed out of the coarser types of mulch product available, with single or dual beaters to break apart mulch before it is spread onto row. As an option, a hydraulic drive bi-directional discharge belt for left and right side discharge enables the operator to spread onto left over rows and save on trips.

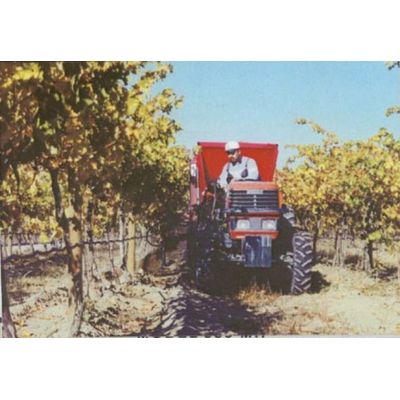

Whatcom - Vineyard Mulcher

The optional twin belt discharge will cover spread two rows at once. Mulch bed width can be tailored to row by adjusting belt speed and diversion flaps. Organic mulch or grape pumice are easily deposited to the desired depth for maximum coverage and efficiency. The twin belt discharge attachment is easily removed and a dual spinner discharge assembly can be installed in minutes. With this unit, material will be broadcast spread across entire row. Spinner Hoods can also be added to now divert product for side dressing of two rows at once. Dual Hydraulic Motor drives with variable spread controls can be adjusted for width of spread and amount of product applied. Whatcom now has 4 types of spreading mechanisms available to fit any growers applications. These combined with our 7 different models enable us to custom build a machine for you.

Whatcom - Model 650 & 850 - Orchard Mulcher

Whatcom Manufacturing’s Mulch Spreaders are specifically designed and engineered for orchards! The inverted V shaped box is ideally suited for maximum clearance through tree rows with minimum branch damage. The lower and narrower design greatly increases stability on steep side hills.

Whatcom - Mulch Spreader

Whatcom Mulchers are specially designed for fast and easy mulch applicataion saving time and money. Our Mulchers are designed from the ground up with the farmer in mind. It is available in multiple sizes with numerous options and features built to accommodate all applications for use with sawdust, shavings, manure, solids, etc…

Fertilizer Spreader

Whatcom Narrow Profile - Model 250 - Fertilizer Spreader

Whatcom Manufacturing`s Stainless Steel Fertilizer Spreaders are specifically designed for the BERRY grower. Extra narrow width and higher capacity will accommodate mature fields and minimize time and trips required to cover larger acreage plantings. Our twin belt discharge evenly spreads fertilizer on two rows simultaneously. This feature in conjunction with the ground driven floor chain provides for concise application rates regardless of ground NP-300 speed.

Whatcom Narrow Profile - Model 300 - Fertilizer Spreader

Whatcom Manufacturing`s Stainless Steel Fertilizer Spreaders are specifically designed for the BERRY grower. Extra narrow width and higher capacity will accommodate mature fields and minimize time and trips required to cover larger acreage plantings. Our twin belt discharge evenly spreads fertilizer on two rows simultaneously. This feature in conjunction with the ground driven floor chain provides for concise application rates regardless of ground NP-300 speed.