Dynatec Systems Inc.

- Home

- Companies & Suppliers

- Dynatec Systems Inc.

- Downloads

- The Dynatec Difference GOLF COURSE ...

The Dynatec Difference GOLF COURSE WATER MINING PROJECT A County-owned golf course in Pitman NJ did not have enough water for irrigation. The fa

The Dynatec Difference

GOLF COURSE WATER MINING PROJECT

A County-owned golf course in Pitman NJ did not have enough water for irrigation. The facility used

well water, and had to withdraw more water than their permit allowed in order to satisfy irrigation

requirements. The challenge therefore was to provide suitable water quality that satisfied their

requirements, and did not exceed the volume that they were permitted to withdraw from the public

sewer.

Evaluation:

The only local source of water available was a local sewer that passed

close to the facility, but on the other side of major divided highway.

Dynatec’s Dynalift™ process was selected, since it has proven to

provide high quality water with non-detect levels of virus and bacteria,

therefore providing safe irrigation for reuse for the golf course.

The Process:

1. Wastewater is pumped from a sewer line several hundred yards

from the treatment facility.

2. The water is screened to remove larger solids. The screenings are

returned to the sewer line via gravity.

3. The screened water is then pumped to the biological system:

Two biological trains consisting of anoxic and aerated zones are used to remove both organic

constituents as well as ammonia from the waste, producing water with non-detect levels of BOD

and low levels of total nitrogen.

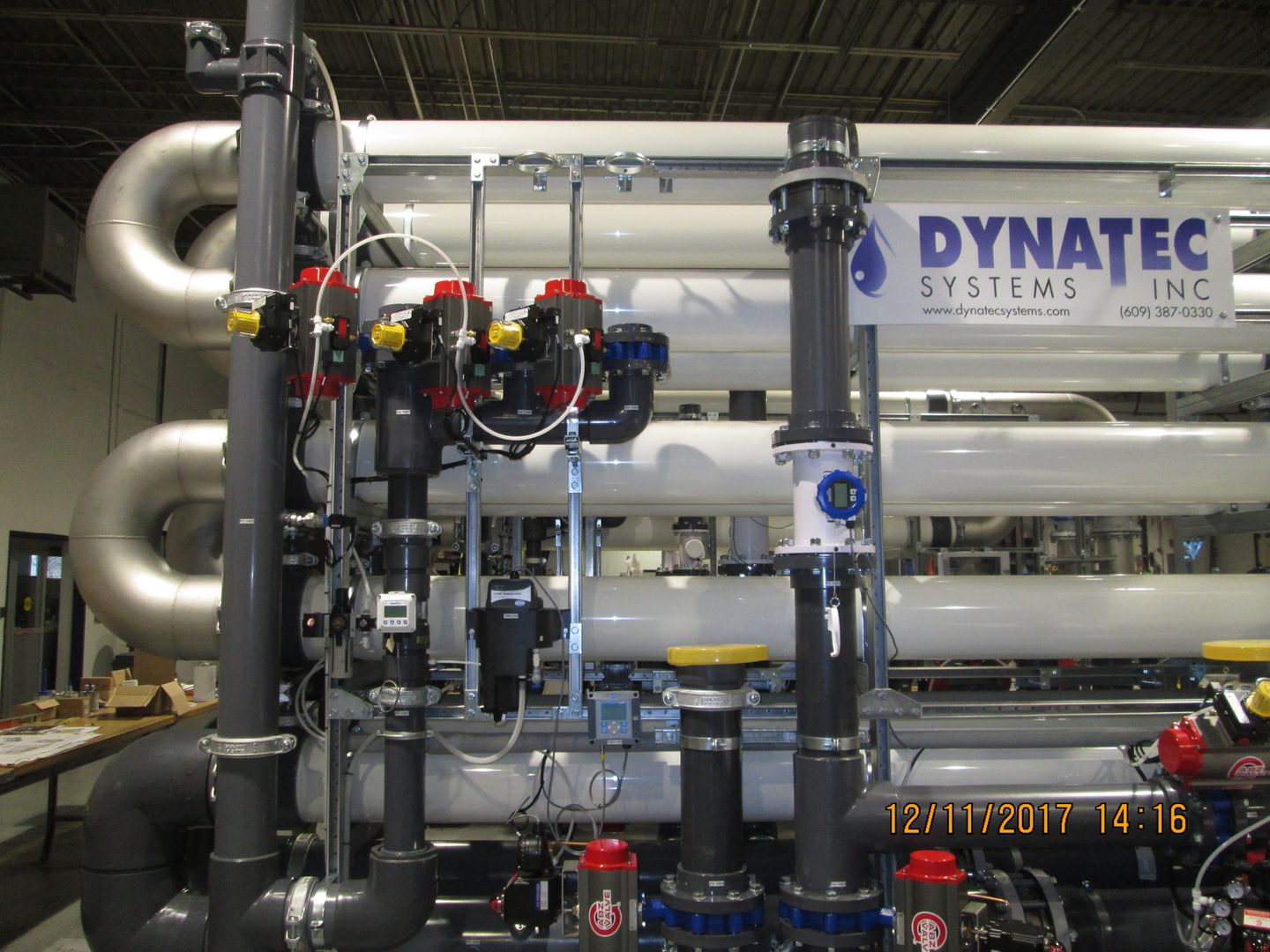

4. The mixed liquor is then separated using two DynaLIft™ membrane racks

The DynaLift™ is an out-of-basin membrane system using 0.03 µm micron ultrafiltration membrane

to separate the biomass from the water, producing water with non-detect levels of TSS.

The DynaLIft™ system is a low-energy system that uses air as a scouring medium to prevent fouling

of the membrane. Periodically, the membrane is backwashed – this is the only type of polymeric

tubular membrane that is capable of being backwashed – to prevent membrane fouling.

The discharged water is stored in a lagoon until required by the golf course. The water is pumped

through pipe that was installed by directional drilling under the highway, where distribution pumps

are then used to irrigate the golf course.

Waste sludge is returned to the sewer line automatically based on operator inputs. The facility is

completely self-sufficient, with all waste products being discharged from the treatment building

underground, and therefore causing no local smell nuisance to local residents.

Conclusion:

The plant operates completely automatically with only limited part-time supervision, and produces the

highest quality water in quantities sufficient for the golf course’s requirements. All the air from the

operation is vented outside the building, making the operating environment safe and pleasant for the

operators. This fact also means that the environment inside the building is no more humid than the

ambient atmosphere, resulting in a non-corrosive atmosphere. Building costs therefore are kept modest,

since no anti-corrosive measures are required in building design.

Significant Savings

· Small footprint saves building cost

· Water reuse provides water that

is not available from the well

· Remote monitoring

· Easy maintenance

Land Development

· Residential Housing

· Office Parks

· Apartment Complexes

· Recreational Facilities

Technology Benefits

Membrane separation system uses

long-lasting tubular ultrafiltration (UF)

membranes

· Simple mechanical process

· Consistent high quality water

· Ability to reuse purified water

· Low operating costs

· Unattended operation

Zero sludge disposal cost

Contaminants Removed

· BOD5

· TSS

· Nitrogen

· Phosphorous

Services Provided

· Systems Design

· Equipment and Installation

· Operator Training

· Maintenance Contract

DBOOM

Retrofit existing conventional

treatment systems

Most popular related searches