- Home

- Companies

- RSK ADAS Ltd

- News

- Preparing for an Environment Agency ...

Preparing for an Environment Agency Inspection

The thought of an Environment Agency (EA) inspection causes stress for many farmers. With broad inspection areas and various regulations to consider, it can be difficult to prepare.

To help alleviate some of the uncertainty, we explore the eight most common reasons for inspection failures and things farmers should consider.

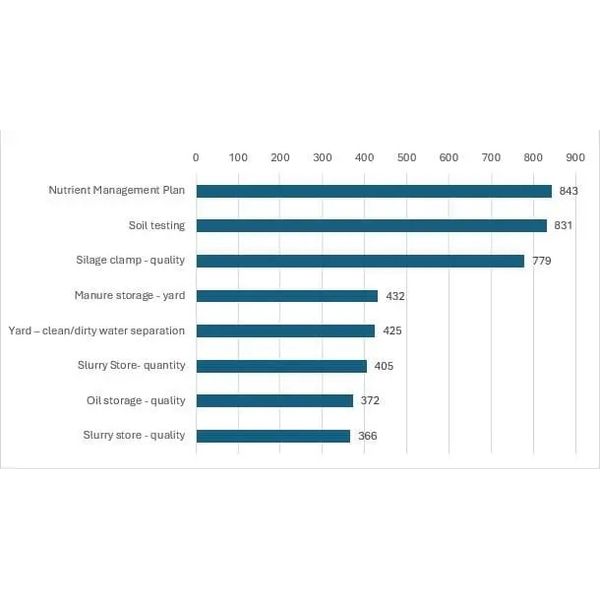

According to the AIC, the Environment Agency completed 4,545 farm inspections in the 2024/25 financial year. EA uncovered non-compliance at nearly half of inspections, issuing a total of 6,870 improvement actions.

A high proportion of these were related to nutrient management planning and soil testing. These are both requirements of the Farming Rules for Water (FRfW).

Research by the UK government in 2024 showed that 33% of farmers didn’t have a nutrient management plan.

The good news is that nutrient management planning and soil testing complement each other well. Both can be resolved quickly with help from a FACTS-qualified adviser.

Don’t view nutrient management planning as a tick box exercise – it is a helpful management and efficiency tool. Fertilisers are expensive – oversupplying nutrients isn’t just poor environmental practice, it affects the bottom line.

You can’t manage what you don’t measure

The old saying ‘you can’t manage what you don’t measure’ highlights the importance of soil testing and analysis. Through regular soil testing – measuring the soil pH, phosphorus, potassium, and magnesium indices – you can make evidence-based decisions on:

- where and how much manure to apply

- which fertilisers to use and how much to put on

Nutrient plans and records can also help those in Nitrate Vulnerable Zones (NVZs) demonstrate compliance with the 250kg of total organic nitrogen per hectare field limit, and NMAX limits for various cropping.

Given that creating additional slurry storage can be very expensive, it’s little wonder that over 10% of improvement actions in the graph above are for insufficient slurry storage.

Manure and slurry are some of the most valuable commodities on the farm, yet are still often viewed as by-products to ‘get rid-off’. Whilst there is a cost to storage and spreading, it is also a vital resource in lowering fertiliser bills and improving soil health. Make storing manures safely and preserving the nutrient content of the manure a priority, as the long-term benefits can be high if used correctly.

There are several pieces of legislation to consider for storing, managing and spreading manure, effluent and slurry. Along with the FRfW, there is NVZ and Silage, Slurry and Agricultural Fuel Oil (SSAFO) regulations.

Under SSAFO, farms producing cattle slurry require a minimum of 4 months’ storage, or 6 months’ storage for pig slurry and poultry manure storage. For farms inside an NVZ, the requirement for cattle slurry storage increases to 5 months’ production.

Field heaps

For farms that are using field heaps to store their farmyard manure, it is essential that:

- the heap is a minimum of 10m from any fresh water such as ditches, streams and ponds; and 50m from springs, wells and boreholes.

- Field heaps are moved at least every 12 months, and a two-year gap should be left before returning to the same site.

- Records are kept of the site locations and dates the sites were in use is key to demonstrating compliance.

Silage clamps

Silage clamps are another key issue during EA inspections. Whilst we often hear of ‘pre-1991’ or ‘exempt’ structures, the reality is that silage clamps regardless of age must not pose a pollution risk.

Structurally sound clamps do not leak through cracked concrete or into earth banks. They also have appropriate drainage to collect effluent which is then diverted to appropriate storage, such as an effluent tank or the slurry storage system.

Fuel oil storage is another compliance issue that falls under the SSAFO regulations.

All fuel oil stores must have a containment area, either a bund or enclosure that is able to hold 110% of the volume of the store. Place tanks on an impermeable surface and do not install within 10m of any running water, drain or ditch.

Our team of fully independent FACTS-qualified nutrient management advisors can pull together a nutrient management plan tailored to your business and situation. Whilst our nutrient plans give you peace of mind for your inspection, they are also a tool to help you to:

- maximise nutrient use efficiency

- improve soil health,

- optimise crop growth potential

- protect the environment

Our farm infrastructure experts have decades of experience supporting farmers with:

- undertaking slurry production calculations

- designing slurry and manure stores

- providing silage clamp designs

- advising on clean and foul drainage

Our advisers keep fully abreast of all current developments and regulations and provide practical on-farm solutions to help you achieve compliance.

For enquires regarding soil sampling, nutrient planning or any farm infrastructure queries, contact the Agriculture and Land Management (ALM) team at ADAS almadmin@adas.co.uk.