- Home

- Companies

- ISM Separator Sp. z o.o.

- Products

- ISM Separator - Aerodynamic Grain ...

ISM Separator - Aerodynamic Grain Separators Technology

ISM Separator produces aerodynamic grain separators with capacities ranging from 3 to 200 t/h. Thanks to the high quality of assembly and low price, our machines for cleaning and calibrating grain are very popular both in Poland and abroad. We can confidently say that our factory’s separators are the most perfect a solution for cleaning and sorting all types of agricultural crops, as well as preparing high-yielding seed material.

- Increased productivity

- High-quality cleaning

- Easy to set up and manage

- Separation of seeds into fractions

- Savings and low energy consumption

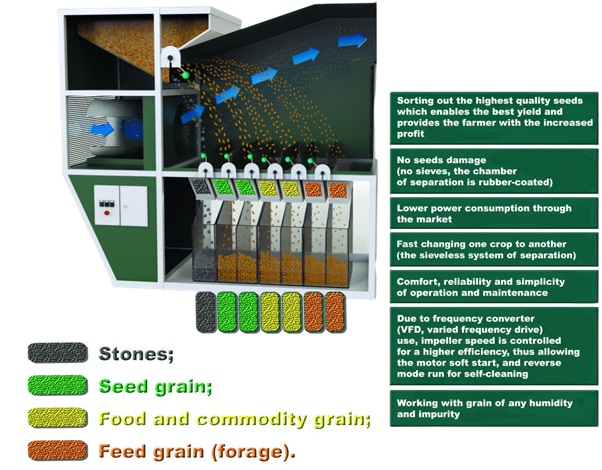

The operation of the machine comes down to changing the grain’s free falling trajectory, the air flow generated by the motor with impeller and further decomposition and division of the starting material into fractions depending on mass, size and shape.

The starting material is fed into the hopper and distributed over the entire width of the tray under its own weight. In this form, the grain enters the chamber separation with a uniform stream, where it is stratified and divided according to mass, size and shape, which is the result of the influence of air flow from the impeller block.

- Cyclone dust collector with an inertial principle of air purification from impurities. The purified air is directed at an angle, as a result of which the contaminated air is cleaned and the impurities settle at the bottom of the chamber and are automatically removed under air pressure through special trays.

- A special system of labyrinth channels with sudden differences in its cross-section. 2 or 3 180 degree rotations release a significant amount of dust

- System for changing the channel cross-section. In many segments, the pressure is significantly reduced, dust particles change their trajectory, hit the channel walls and settle. The cyclone chamber allows you to purify the exhaust air by 80 percent. In the first settling chamber, the air is purified by approximately 12 to 15%. In the second and third chambers, almost complete cleansing occurs.

- Possibility of installing the device in open and closed rooms without additional air purification systems.

- Improved separation quality by reducing air flow turbulence in a closed circuit.

- Electricity savings up to 30% compared to a machine without a pedestal.

- Additional grain drying through aerodynamic air heating circulating inside the separator.

- Increased acoustic insulation (noise level reduced from 87 dB to 57 dB).