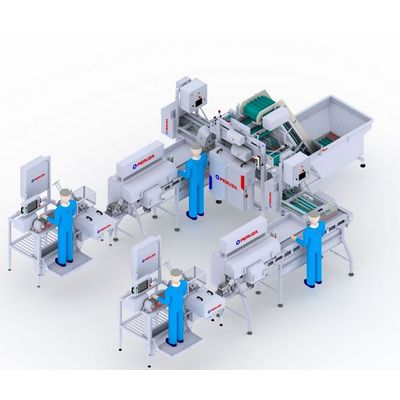

The autopacker for vertical cans is designed as a multi-purpose packing machine for food products; the machine can be used on modern fish processing factories that seek higher performance and lower costs.

The autopacker is suitable for processing different types of fresh, quality frozen, and defrosted pelagic fishes: Sardines, Mackerel, Herring, etc. The auto packer machine handles fish processing from A to Z – it automatically receives, de-heads, guts, and cans fish

into vertical cans. The machine can also be used for canning various long products, not only fish but also asparagus, cucumbers, sausages, etc. On average, the autopacker produces up to 120 cans per minute and works with Jitney, Tall, and Buff can types.

The auto packer machine can be complemented with a 3-cut device that cuts fish to the appropriate size. For example, if the length of a de-headed fish is 15 cm and the can is only 10 cm long, the device will cut these extra 5 cm off.

The machine that performs all steps of fish processing, from heading to canning, only needs four operators. This approach to production reduces or even completely removes the need for a workforce and reduces labor costs. Other benefits of autopacker include clean and precise cuts, low water consumption, and a higher yield ratio for more efficient and economical fish processing.

- Clean cuts without damaging the fish

- Low water consumption

- High yield

- Easy maintenance and cleaning

- Pre set fish count into cans

- Just 4 operators

Technical characteristics:

- Productivity: 120 cans per minute with only 4 operators

- Types of cans used: Jitney cans, Tall can, Buff can

- Fish processed: Sardine, mackerel or similiar

- Condition of fish to achieve max capacity: Fresh or quality frozen and defrosted. Bad quality fish will reduce capacity and increase error percentage

- Length of fish: 110 – 240 mm

- Operators: 2x1 for nobbing operation 2x1 for can packing quality control

- Dimensions: 8800 x 5600 mm