- Home

- Companies

- Biomasser by Asket

- Products

- Biomasser Duo-Set - Machines for Straw ...

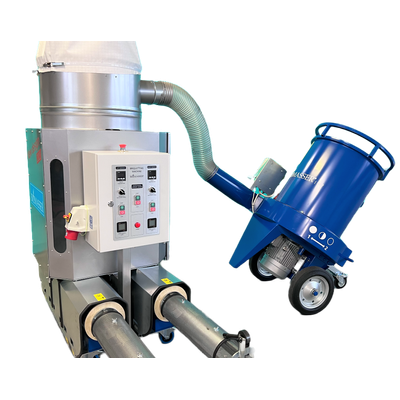

Biomasser Duo-Set - Machines for Straw Briquettes

Biomasser Duo-Set is a small, complete set of machines for straw briquettes production composed of briquetting machine Biomasser Duo and straw shredder Tomasser RK . The set is designed for individual users and small farms for the production of briquettes for their own needs and the needs of the local community. Surplus briquettes can be sold on the local market. The idea of Biomasser technology is to notice the renewable resources around us and transform them into added value for the closest community. Let's use what we in our surroundings, within our reach, as not to transport the fuel unnecessarily. Read more about briquettes and their use.

Biomasser Duo-Set is a small, complete set of machines for straw briquettes production composed of briquetting machine Biomasser Duo and straw shredder Tomasser RK .

The set is designed for individual users and small farms for the production of briquettes for their own needs and the needs of the local community. Surplus briquettes can be sold on the local market.

The idea of Biomasser technology is to notice the renewable resources around us and transform them into added value for the closest community. Let's use what we in our surroundings, within our reach, as not to transport the fuel unnecessarily. Read more about briquettes and their use.

Simple principle of operation

Put loose straw or small cube (after removing strings or net) into the shredder. The shredder cuts it into pieces that go directly to the container of the briquetting machine. Then the agitator feeds the chopped straw to the briquetting chamber, where the material is heated and compressed. We get 100% natural briquette .

Elements of the set

The set is composed of the elements ensuring an effective and comfortable work, that is:

- shredder for lose straw and small cubes Tomasser RK

- modular briquetting machine Biomasser Duo

- filter bag that reduces dust generated in the workplace during raw material chopping.

By choosing Biomasser, you get innovative and functional values:

- you make usage of higher moisture content - the exceptionality of Biomasser technology is that it processes the raw material without any additives, adhesives, flours, binders and of moisture content of up to 30% what means that it does not need to be dried before briquetting – it’s a unique feature by world standards.

- you decide about the hardness of the briquette – by Biomasser you can adjust the hardness of the produced briquette. This increases the scope of its use, as it can be used both as fuel and as hygienic bedding for animals, so as bedding having reduced amount of microorganisms, bacteria and fungal spores compared to straw or hay harvested straight from the field.

- you get proven and ecological technology - European Statement ETV .

Biomasser technology, as the first in Europe, received the Environmental Technology Verification Statement under the European Commission's program, confirming its eco-innovation and supporting climate protection.

Biomasser is a verified machine, and in addition 95% recyclable and produced in a plant powered by electricity produced from solar panels, heated with straw briquettes and electric boilers. All of this makes our products environmentally friendly and helps to protect our planet.

- Input material (raw material) : non-woody biomass such as straw, hay, reed

- Material length : 1cm up to 5cm

- Material moisture content : 10% up to 30 %

- Material temperature : +5°C up to +30°C

- Product : briquette of 8cm diameter with a hole inside

- Productivity : up to 160 kg/h

- Installed power : 20,25 kW

- Terminal : 32A, 32A

- Power supply : 3 x 400V, 50Hz

- Power consumption : ~70 kWh per 1 tonne of briquettes

- Dimensions (L / W / H) : -

- Weight : 680 kg

- Workplace temperature : +5°C up to +30°C

- Workplace conditions : roofed place with appropriate ventilantion

- Mobility : no

- Shredder included : yes - Tomasser RK

- Service : 1 person

- Notes : machines equipped with wheels

the productivity of the machines depends on the type of raw material, its moisture content and hardness of the briquettes produced