Alapala Construction

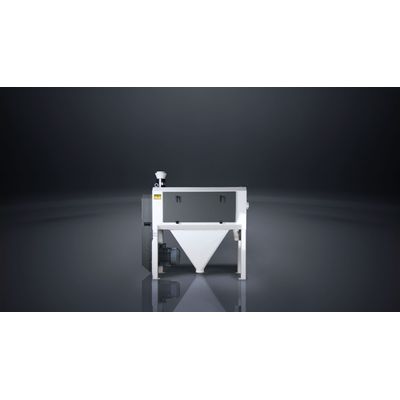

Alapala - Model DKFS -Bran Finisher for Grain Milling

The Bran Finisher DKFS is designed for efficiently enhancing flour yield by using centrifugal action to separate the floury endosperm from bran. This technology minimizes starch content in offal and ensures optimal flour retrieval. The machine operates with a horizontal rotor equipped with wings that propel the product towards a pre-sized screen. This motion allows flour particles to pass through the screen while directing larger bran pieces to a discharge outlet. The Bran Finisher DKFS is integral in grain milling processes where precision and efficiency in separating flour from bran are crucial. The equipment's design emphasizes robustness and effective separation, making it a valuable asset in any modern milling operation focusing on high-quality flour production and waste reduction.Most popular related searches

- Screw for product introduction with centrifugal disc

- Welded sheet structure

- Statically balanced rotor fitted with four beaters, each with adjustable angle and distance to the cover

- Shaft mounted on a double row of spherical roller bearings and supports

- Cover made of perforated sheet steel specially shaped to avoid internal turbulence

- Adjustable paddles to vary the rate of product flow through the machine

- Two wide doors permit easy access for inspection and screen removal

- Low energy consumption and high output

- Minimum and easy maintenance

- Durability and long lifetime

- Practical and easy cleaning process

- Quick and easy screen replacement

- Noiseless working condition

- Trouble free operation

- Less space is needed, when double model is used

- Different air connection possibilities per request

The product is thrown towards the screen by means of a wing - fitted rotor, which is rotated horizontally; consequently, the flour and bran are separated from each other. Due to centrifugal force, the product is thrown towards the screen whose size is selected beforehand. During the screening process, flour passes through the screen and larger sizes of bran are directed to the discharge outlet.