- Home

- Companies

- AG-Projekt

- Products

- AG-Projekt - Model SD ESR - Canopy ...

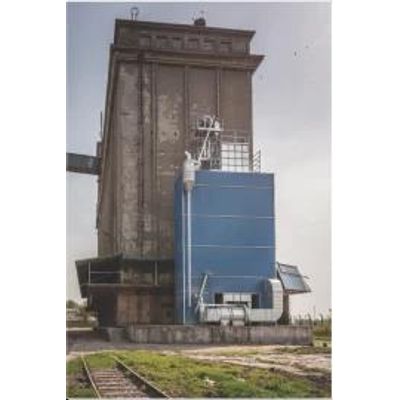

AG-Projekt - Model SD ESR -Canopy Dryer with External Recuperative Duct

The continuous roof canopy dryer SD ESR with external recuperative duct is characterized by dust-free operation, affordable price, easy and safe operation, and a modern design allowing for the extension of the dryer to increase its efficiency. The hot air recuperative channel allows for 30% energy savings. This dryer model is chosen by demanding customers who want to dry mainly corn.

Cereal, rapeseed or maize grains for drying are delivered to the hopper hopper segment from above using an external transport device. It fills all cooling and drying segments, and largely the charging segment, creating a pile in it.

The air heated by the heating furnace to a certain temperature is drawn through the exhaust fans to the warm air duct, then flows under the inlet roofs of each drying segment. The air, passing through the grain layer, receives moisture from it and gets under the canopies with axes shifted in relation to the inlet canopies. Moist air passes to the cold air duct, from which exhaust fans lead them outside. This process of drying grain takes place at all levels of drying the columns.

The grain filled from above moves down and, passing between the roofs, is heated and dried. After passing the grain through all drying segments, the column goes to the cooling section, in which cold air at ambient temperature flows through the grain, lowering its temperature to almost ambient temperature. After cooling, the dried material moves to the selection element. Dialing efficiency can be precisely adjusted from a few kilograms to several dozen tons per hour. This makes it possible to precisely adjust the grain flow through the dryer so that its final moisture content is correct.

The selection element has a mechanism of sliding shelves, allowing the grain to pour into the hopper, from where it spills outside the dryer to a series of transport devices that transfer them most often to warehouses, forwarding silos or for further processing.

In place of dry grain, moist grain comes. During the operation of sliding the sliding shelves, the exhaust fans automatically reduce their rotation, thus reducing the amount of extracted air, which prevents the release of dirt from the settling chamber and allows them to fall automatically to the bottom of the chamber. After a while, the fans automatically increase efficiency, this process is repeated cyclically. In addition, on the settling chamber, the fans are located in a built-in chamber with silencers, which makes it one of the quietest least dusty dryers on the market.

We encourage you to contact us by phone or e-mail regarding the SD DRYER. We provide advice in the selection and configuration of an assortment. Our experts will explain all technical matters related to AG-PROJEKT products.