- Home

- Companies

- Southern Drip Irrigation Ltd

- Products

- Zimmatic - Centre Pivots

Zimmatic - Centre Pivots

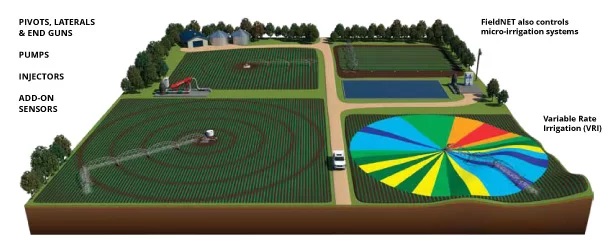

Zimmatic pivots are made with precision with each component is carefully designed to run trouble-free for years to come. Technologically advanced Zimmatic control panels that can also be added to any brand of centre pivots.

Farmers are choosing to increase the value of their assets by eliminating idle land. Irrigation allows for more crop versatility and higher yields as it grants the ability to hedge against the weather. It allows the grower to avoid the negative effects of dry years, spotty moisture patterns and removes the waiting period for moisture to begin the growing season. Mechanical move irrigation, such as a centre pivot, has been at the leading edge of farming technology; it is a great management tool for increasing efficiency so growers can stay competitive.

A centre pivot is a mechanized sprinkler system that irrigates crops in a circular pattern around a pivot point. A span of pipe is supported on an A-frame with wheels and the pipe transports water to attached sprinklers.

Pivots are capable of applying water, fertilizer, chemicals, and herbicides over large areas of land to increase yields while saving time and costs.

Zimmatic pivots, created by Lindsay Corporation, continue to be the leading brand of pivots and laterals as they deliver the most durable and technologically advanced solutions for your field.

10,000 acre Dee River Ranch in Aliceville, Alabama, owned by Annie Dee, Mike Dee and their 10 brothers and sisters, implemented seven Zimmatic centre pivots with control panels fitted with FieldNET advisor.

Before irrigation, their average dryland corn yield was 103 bushels/acre, while after installing a Zimmatic pivot sprinkler system the average corn yield increased by 77% to 182 bushels/acre.

This meant a 79 bushel/acre increase and an additional $553 additional revenue per acre. Originally their projected payback period was 5 years, but with the improved yields and other efficiencies they found, they moved that up to a two-year plan by ordering 11 additional Zimmatic pivots for the following spring.

Zimmatic pivots are made with precision; each component is carefully designed to run trouble-free for years to come. This attention to quality even allows old pivots to be updated with advanced add-ons and run like new, as the most important part of a pivot is its enduring, modular and galvanized structure. This enduring quality propels Zimmatic pivots ahead of their competition.