- Home

- Companies

- Phoenix Composting Toilets UK Ltd

- Products

- Phoenix - Composting Toilet

Phoenix - Composting Toilet

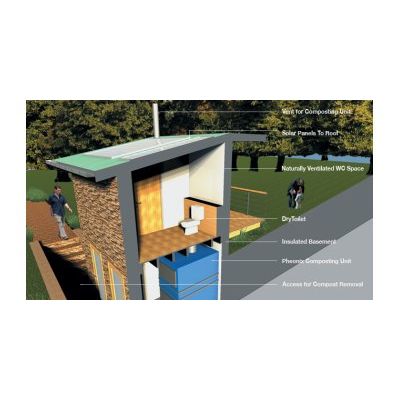

Phoenix Composting Toilet conserves energy and water, and is friendly to the environment. The Phoenix Composting Toilet is manufactured in Advanced Composting Systems climate controlled factory near a peat bog south of Whitefish, Montana, a resort and railroad town west of Glacier National Park. Many have been constructed in environmentally sensitive areas of the United States and is widely used as public facilities in the National Parks where it has been approved for use by all Federal Agencies. Advanced Composting Systems, has over thirty years experience designing, manufacturing, and installing toilets and prefabricated buildings. Phoenix Composting Toilets UK Ltd has a licence to supply and install the Phoenix toilet in the UK and Europe and it`s staff has wide experience in the construction of waste water and environmental treatment plants as well as general construction.

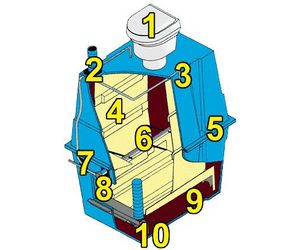

- One or two toilets connect to the Phoenix with 12-inch diameter chute. The toilets are molded from vandal resistant polyethylene and ABS plastic.

- Ventilation is provided by an efficient, 5-watt, direct current fan. The fan housing is mounted directly to the tank for easy maintenance. A small power supply or a photovoltaic system provides the energy. Flexible 4-inch duct and 4-inch PVC pipe are installed easily. image

- The Phoenix is fabricated from rotationally molded solid and foamed crosslinked and linear polyethylene, assuring many years of service. The tank is durable, corrosion resistant, leakproof, and continuously insulated.

- Continuous air baffles along the tank sides provide aeration of the compost pile without interfering with compost movement. Their large surface area allows the insulated tank to be readily warmed with circulating air from a heater or active solar collector.

- A leakproof joint is accomplished with a gasket and interlocking flange. Assembly requires only a few bolts and no caulking.

- Rotating tines control the downward movement of the material in the compost pile. The big Phoenix Model 201 has three tine shafts, each above the other. The Model 200 (shown) has two shafts, and the Cabin model has one. (For clarity, only one tine shaft is shown in this illustration.)

- Air enters the Phoenix through a screen inlet. A sealed path for ventilation air, and a large contact area, increase ventilation efficiency and allow supplemental heating.

- Finished compost is removed easily through the lower access door from the entire bottom of the Phoenix assuring maximum and uniform retention time.

- The accumulated liquid and/or fresh water is sprayed on top of the compost pile to maintain moisture and inoculate the pile with compost-friendly micro-organisms. The excess liquid is drained to a leach field, to an evaporator, or to a holding tank.

- Liquid is separated from the solids by a screened baffle and resprayed, or drained, from the Phoenix. The drain connection can be made from either side through an inch-and-a-half flexible hose.

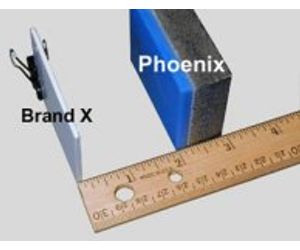

The Phoenix`s tank wall is fabricated from rotationally molded, crosslinked polyethylene (blue) and foamed linear polyethylene . The combination provides exceptional strength, corrosion resistance, and thermal insulation. All other components are selected for strength, durability, and corrosion resistance.