- Home

- Companies

- Henan Lane Heavy Industry Machinery ...

- Products

- Lane - Model 3-15T/H - Compound ...

Lane - Model 3-15T/H -Compound Fertilizer Production Equipment

Compound Fertilizer Production Line is used to produce compound fertilizers mixed with a variety of nutrients- It consists of fertilizer granulator, mixer, screening machine, packing machine and other equipment, which can be adjusted and expanded according to the demand-Compound Fertilizer Production Line can mix different kinds and proportions of fertilizer raw materials together to make granular, easy-to-store and easy-to-decompose compound fertilizer products.

Compound fertilizer production line raw materials:

- Nitrogen raw materials: ammonium chloride, ammonium nitrate, urea, etc.

- Phosphorus raw materials: diammonium phosphate, heavy calcium superphosphate, calcium superphosphate, etc.

- Potassium raw materials: monopotassium phosphate, grass ash, potassium chloride, potassium sulfate, etc.

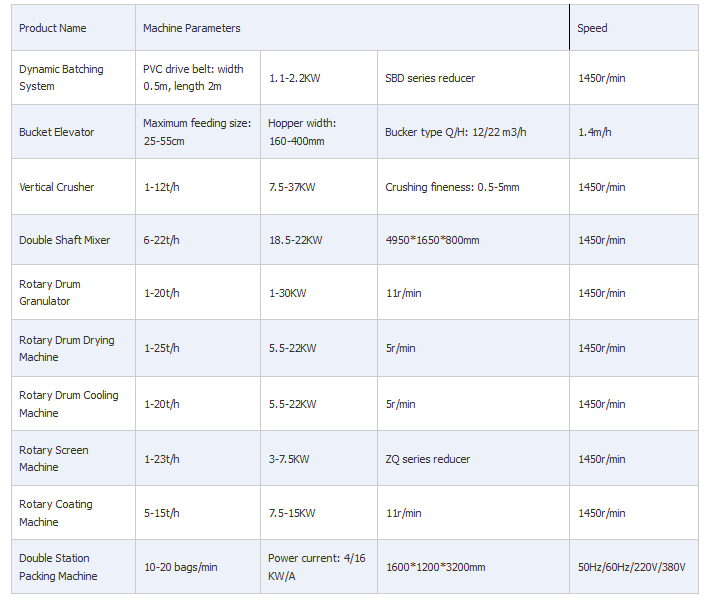

The following is the conventional equipment included in the compound fertilizer production line, which can be adjusted according to the customer`s needs for reduction or expansion-

- Batching: the raw materials required for the production of compound fertilizer into the batching bin, according to the formula of compound fertilizer and production speed to adjust the speed of feeding.

- Crushing: the raw materials are crushed, and the crushed raw materials reach the fineness of particles required before granulation.

- Mixing: Mixer to mix the raw materials evenly.

- Granulation: granulation with rotary drum granulator or double roller granulator (the use of double roller granulator can be removed from the back of the drying and cooling process, direct granulation of dry powder, but granulation before the crushing of the material fineness requirements are higher).

- Drying: After granulation is completed, use the dryer to dry the fertilizer particles to remove the moisture inside and prevent the fertilizer particles from lumping.

- Cooling: In order to improve the productivity and output, use the cooler to cool the fertilizer after high temperature drying, so that its temperature is reduced to not more than 5 degrees Celsius above room temperature.

- Screening: Use a screening machine to screen the fertilizer particles. Unqualified particles are crushed, returned material is sent to the mixer and then granulated, qualified particles are sent to the next process.

- Coating: Surface coating of qualified fertilizer particles to prevent the fertilizer from moisture caking.

- Packing: The finished granules will be sent to the finished product warehouse, and then finally bagged through the packing scale.

- Our production line is equipped with PLC centralized control system, you are able to control the operation of each machine in the production line at any time from the console, avoiding any link problems, reducing labor costs and lowering the error rate.

- The production line is flexible and stable, and can produce different compound fertilizers through different ratios of raw materials.

- The production line has the design of re-materialization, which greatly improves the production efficiency and avoids the waste of raw materials.

- The production line provides all the equipment, including dust removal equipment, burner, belt machine and other ancillary equipment, giving you a complete and intimate shopping experience!

Compound fertilizer production line has the advantages of high efficiency, automation and environmental protection. It can produce compound fertilizer with balanced nutrition and stable quality according to the needs of crops, and improve the efficiency and yield of agricultural production- Compound fertilizer production line can also realize environmental protection and resource saving through the treatment and recycling of waste gas and waste water. We look forward to communicating with you and carrying out honest cooperation!