- Home

- Companies

- Zeno Farm Machinery

- Products

- Zeno - Model 4G80/4G100/4G120/4G150 - ...

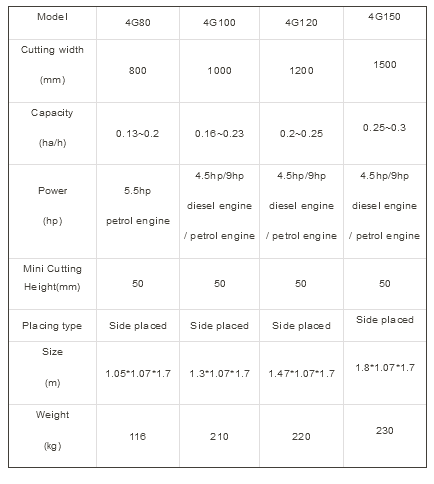

Zeno - Model 4G80/4G100/4G120/4G150 -Corn Reaper Machine

Corn reaper machine can be used for harvesting maize, chili, soy,sorghum etc.The maize reaper machine is powered by diesel or gasoline engine, double wheel, automatic walking, efficient cutting. The corn harvester can walk automatically, the blade is sharp and the corn is not scattered after the cut of the alloy steel, and it is neat to the side, so that it can be manually strapped.

- Model: 4G80/4G100/4G120/4G150

- Capacity: 0.13~0.2ha/h

- Power: Petrol engine/diesel engine

- Application: Corn,chili,sorghum

This mini corn harvester machine combine with the small machine size, it is easy to operated and suitable be used in the hilly and mountainous area, etc, which big combine maize harvester can’t working.It can satisfy various requirements of different users.

Multi-function

Maize harvester machine can be used for corn,soybean, forage grass, rape, pepper, reed, corn, salix integra, sorghum, stevia rebaudiana, chilli, sesame, millet

Labor Saving

It releases people from busy physical labor, saves people the problem of hard work in the hot sun.The investment is small and is easy to recover. It should be the best choice with the excellent work mobility and maneuverability.

Best Adaptability

The corn harvester machine body is relatively small, so there is no restrictions to the planting spacing and no need to clear the way. Thus it can be widely applied to harvest corn in plain regions, hilly regions and corn interplanting regions.

Powerful engine

Diesel engine or gasoline engine for you choose.Engine are using high technology, powerful and stable, the cylinder wall by chrome-plated, coupled with the enhanced crankshaft, the engine life extension, the performance to achieve good match.

High Quality

The corn harvester machine blade adopts high quality alloy steel cutter, transmission part adopts advanced high frequency quenching process, high resistance to wear, transmission part connection tooth accurate and precision, movements smooth, greatly reduce the maintenance cost of users.