- Home

- Companies & Suppliers

- Downloads

- Gestal Focus - Model GESTAL Select - ...

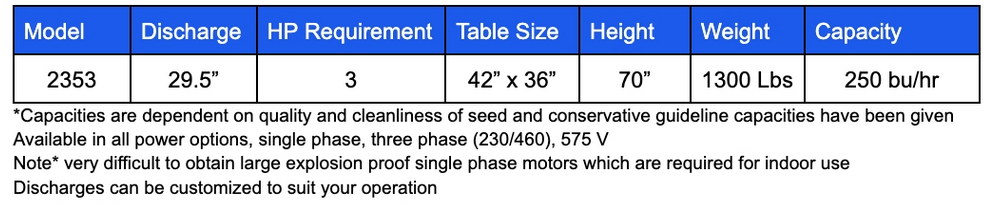

Garratt - Model 2353 -Destoner

A Destoner is most commonly used to separate heavy material out of edible product. The Garratt Destoner effectively removes mud balls, stones and other heavier debris from desired product. Our Destoner drive is very similar to our Gravity Table design although there is a few differences. The Destoner has a shorter stroke and a steeper incline creating a more aggressive throw allowing the heavier product to go over the high side. Another difference is our Destoner has significantly more air per square foot of deck.

Generally our Destoner is paired with our Gravity Table, this works because we take about a 40% cut of the heaviest material and that material will pass over the Destoner.

The Garratt Destoner features an easily interchangeable deck, held down by four bolts.

Adjustments

Shake speed, fan speed, deck pitch and all major operating adjustments can easily be made on the go.

Garratt Gravity Tables use common components that can be purchased at almost any local supply store.

All Garratt Destoners are countered balanced which reduces vibration and increases longevity of the unit.

Low Horsepower Requirements

The Garratt Destoner is powered by two motors, one two horsepower motor and one, one horsepower motor.

Like all Garratt Equipment the Destoners are built heavy. The 1/4″ thick steel frame provides extra stability and reduced vibration which can increase the lifespan of the machine.

Unlike Destoners that feature airflow adjustments in increments, Garratt Destoners feature an air-flow system that is adjusted by a spring loaded split sheave variable speed control. This allows the operator to make micro adjustments. The deck shake is adjusted by a variable frequency drive.