OPaLL-AGRI, s.r.o

- Home

- Companies

- OPaLL-AGRI, s.r.o

- Products

- Opall - Model PEGAS II SM - Disc Harrow

Opall - Model PEGAS II SM -Disc Harrow

The PEGAS II disc harrows are universal tools for post-harvest treatment of the soil by stubble cultivation; they can also be used in pre-sowing preparation.

Most popular related searches

disc harrow

mounted disc cultivator

post-harvest treatment

post-harvesting system

stubble cultivator

disc cultivator

post-harvest

harrow

mounted cultivator

agriculture machine

A real hard worker which easily handles all the pitfalls of the condition. After you test it, it is very likely that it will become your faithful helper even in pre-sowing preparation. This is the new PEGAS II SM semi-mounted disc cultivator.

Product description

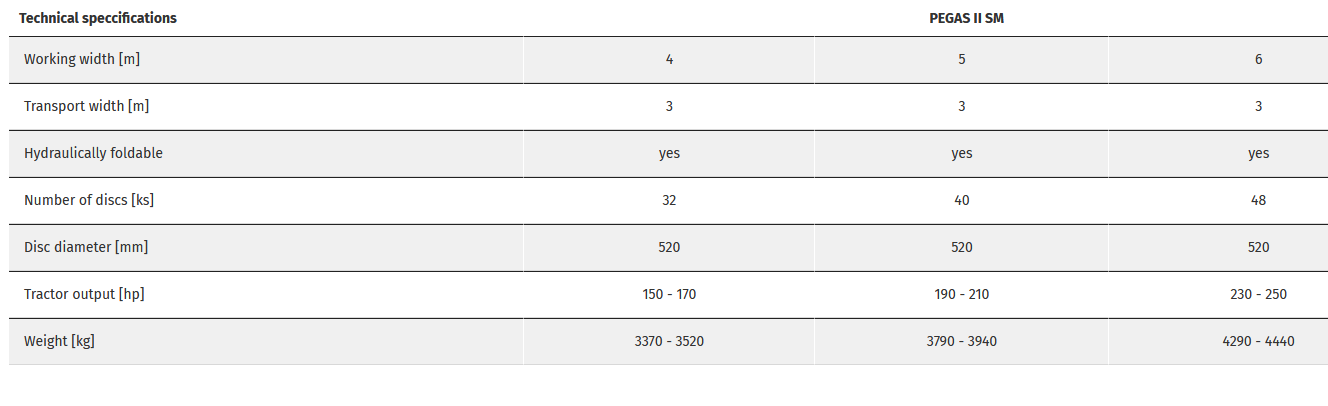

The PEGAS II disc harrows are universal tools for post-harvest treatment of the soil by stubble cultivation; they can also be used in pre-sowing preparation. Thanks to working widths distance up to 3 meters is PEGAS II SM designed for tractors from 150 horsepower. The PEGAS II disc harrows are manufactured with rubber impact absorbers for protection of the discs and thanks to a 520 mm disc diameter they can process soil up to a depth of 15 cm.

Why OPaLL-AGRI PEGAS II ?

- Tradition of agricultural machinery production since 1995Disc harrows combine years of experience with the use of modern production technologies

- Precise processing to the smallest detailHigh-quality processing ensures your long-term satisfaction and precision work

- Prototype testing under the most demanding conditionsBefore launching into the market, the machine has been tested under the toughest conditions to develop a truly precise assistant for your farm

- Unique angle of disk positioningDisc positioning angle allows for higher work speed while maintaining low power consumption and excellent work quality

- Simple design without lubricating pointsThe machine is easy to maintain due to maintenance-free bearings

- Choice of three types of back-up rollersFor optimal work in your conditions, you can choose from tubular, flex or cracker rollers

- Maintenance-free bearings with perfect external protectionSuitably chosen shape and systematic arrangement of safety rings and caps ensures excellent protection against dust, dirt and mechanical damage and thus ensures long service life of all bearings of the machine

- Securing rubber cylinders secured against sliding outThe rubber cylinders are fixed mechanically in the unit with rubber stoppers

- We have our own production of wear partsWear parts made of special abrasion-resistant steel have a long service life

- Semi-mounted version

- Working widths of 4 • 5 • 6 m

- Two rows of ? 520 mm diameter discs

- Rubber impact absorbers secured against slide-out

- Double-row maintenance-free ball bearings

- ? 550 mm tube bar supporting roller

- Rear reflexive plates

- ? 600 mm cracker roller

- ? 600 mm u-ring roller

- ? 600 mm double u-ring roller

- ? 515 mm rubber roller

- The tube bar and flat bar rollers ? 400/400 mm