- Home

- Companies

- Future Fortune Industry Co., Ltd

- Products

- Future Fortune - Model SLHS - Double ...

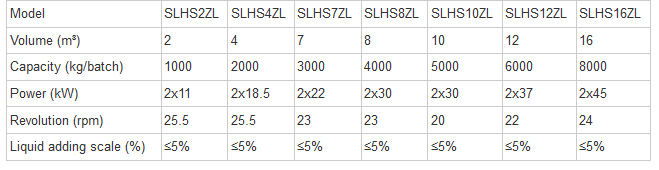

Future Fortune - Model SLHS -Double Motor Twin-Shaft Paddle Mixer

The double motor twin-shaft paddle mixer is used for dry and wet mixing of granular and powdery materials. The paddle design ensures high mixing action and uniform distribution of essential nutrients, vitamins and minerals in the fine mixture. The mixer is used for mixing different powder and granular components with or without added liquids in the production of food, premixes, pet food, aquafeed and animal feed.

Mixer in feed pellet production line

Mixers play a crucial role in feed production. It can be said that if the batching system is separated from the mixer, production will become meaningless even with the most advanced manufacturing process. In feed pellet production, it`s crucial to achieve a consistent distribution of various ingredients such as grains, vitamins, minerals, and additives. The twin-shaft paddle mixer ensures that these components are evenly distributed throughout the mixture, preventing issues like ingredient segregation and ensuring every pellet contains the necessary nutrients.

Therefore, the quality and performance of the mixer are directly related to the survival and development of the feed mill. Stable performance of the equipment will not only help the company continue to profit but also reduce the large maintenance costs.

- Mixer rotors are directly driven by two imported gearboxes;

- Simple structure, compact, small installation space;

- Stable operation and high efficiency;

- Higher reliability, long service life and low maintenance costs;

- Wide applicability, large effective volume, can add a variety of liquids such as water, molasses and oil.

- Smooth operation and gentle mixing without damaging the performance of raw materials.

- Short mixing cycle (45-60s/batch), high mixing uniformity (CV≤5%, up to 3%).

- Patented double-leaf discharge control mechanism, fast discharge speed, no material leakage and no material retention.