- Home

- Companies

- AGRO-EKO Ltd.

- Products

- Agro-Eko - Ecological Waste Apparatus ...

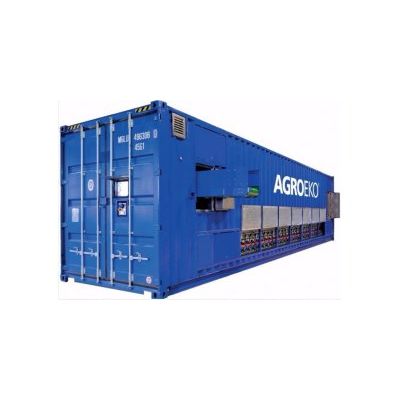

Agro-Eko - Ecological Waste Apparatus (EWA )

EWAfermentor (Ecological Waste Apparatus) is certified device for processing of biodegradable waste (BDW), including sewage sludge and animal products according to the EU Regulation 1069/2009 EC.

- Thermal insulation of the fill - CLIMATE CONDITIONS DOES NOT AFFECT THE PROCESS

- System of turning over the fill - PERFECT RESULTS THANKS TO MIXING OF THE FILL

- Intensive airing of the fill - CONTROLLED BY PC

- Software controled hygienization of the fill - REMOTE CONTROL

Aerobic fermentorEWAgained an European certification for animal by-products treatment by regulation EU 1069/2009 and AGRO-EKO is with this technology categorized as aBAT(best available techniques)

EWA fermentor consists of thermically insulated operation space, system of injectors for intensive airing of the fill, system of fill turning over consisting of segmented floor and flight bar conveyor placed on the inside of the fermentor, and integrated device for loading and unloading. All technology points are placed inside ISO 40track container (ALL IN ONE).

The fill temperature rises above 70ºC and proteins are gradually denatured. High fill temperatures for defined time period cause inactivation of present bacteria and pathogenic organisms (viruses, bacteria, leaven, mould, protozoons, and worms). This process is called thermofilic aerobic stabilization and hygienization of the fill. Due to high temperature the number of microorganisms is decreasing and weed seeds loose their germinating capacity. It takes 48 - 96 hours.

After the thermophilic aerobic fermentation is finished the fill is stabilized and hygienized. As its qualities have been essentially changed it is further on called fermentate. It can be used as compost for agrotechnical use or compost for energetic use (biofuel).