- Home

- Companies

- Sanovo Technology Group

- Products

- BreakerPro - Model 12 - Egg Breaking ...

BreakerPro - Model 12 -Egg Breaking Machine

Developed to have the highest yield in the industry and the lowest possible environmental impact. It is equipped with state-of-the-art solutions, setting new standards for egg breaking machines.

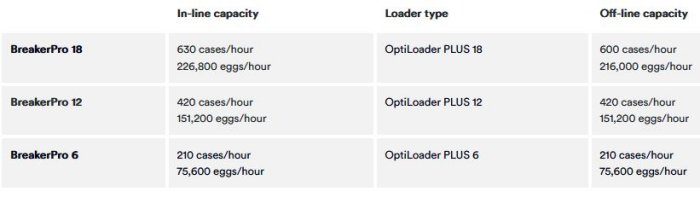

The breaking machine is pushing the boundaries of what`s possible in regards to maximizing yield. Among all egg-breaking solutions in the market, the SANOVO BreakerPro has the absolute highest yield and most effective sustainability solutions, enabling our customers to produce at world-class performance level while protecting the environment. The BreakerPro 18 is the largest model available in the series and can process up to 151,200 (420 cases/hour).

All BreakerPro models come with an optimized gripper design, a longer machine frame, and an optional egg white recovery unit, which together can achieve up to 1% higher yield. On top of that, the BreakerPro comes with a green design, achieved through an optimized CIP system, leading to a reduction in water and chemical use and by ensuring that no water spillage occurs. The BreakerPro also introduces a new advanced multi-color touch panel, multi-function LED bars, and an optimized scanner system - all to ensure the highest possible product quality and an improved operator experience.

- Up to 1% higher yield resulting in a higher ROI

- Green product design resulting in utility savings (water + chemicals + power)

- Optimized yolk cup design and scanner system for cleaner egg white and higher product quality

- New and improved multi-color touch panel, for easier operating and maintenance of the machine

- Better and faster machine adjusting for increased uptime

- Enhanced work environment for the operator by eliminating loose covers

Optimized yolk cup

The yolk cup has been re-designed with a new angle and depth to eliminate sliding yolks. This results in less product spillage and better overall product quality for our customers. We use food grade polyethylene cups instead of stainless steel cups, due to following advantages:

- Better egg white scanning result (no light reflection)

- Up to 40% lower power consumption (lighter drive chain)

- Less wear and tear

- Less noise during production

- Lower risk of severe damages in case of accidental dropping cups

- Best possible design due to unlimited molding possibilities of plastic (limited for steel -> compromises in yield optimization)

Egg white recovery unit

The egg white recovery unit ensures a higher yield by extracting egg white stuck in the shell before the shells are disposed from the breaker. This results in up to additional 0.5% of final product that can be processed as edible! The module comes as an option and can be selected based on your requirements.

Servo motors instead of belts

We discontinued the use of belt drives and introduced servo and gear motors in the BreakerPro. This solution minimizes the risk of downtime, as the gear- and servomotors are more reliable. Furthermore, it simplifies the adjustment when commissioning the breaker as well as during maintenance.

Optimized egg crackers

The crackers in the BreakerPro have been optimized with a new backstop designed into the gripper heads. The optimized egg crackers ensure a more controlled cracking of the eggshells and thereby optimize the draining of the shells, thus resulting in a higher yield.

Optimized CIP system

The CIP system has been optimized to reduce the need for water and chemicals. This has been done by eliminating the need for an external CIP tank. Instead, the bottom of the BreakerPro is used as reservoir for the CIP fluid. If an even further reduction is required, the BreakerPro has an option for being equipped with a pre-flush tank.