- Home

- Companies

- Falcon Srl

- Products

- Falcon - Model Ø 63 - 75 - 90 - 125 - ...

Falcon - Model Ø 63 - 75 - 90 - 125 -Spiral Livestock Transport Systems

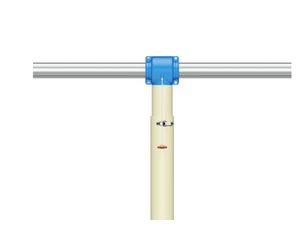

N°: Description

1: Drive unit

2: Hopper

3: Spiral

4: Discharge

The rotation of the spiral (3) through the pipes is made by a drive unit (1) located at the end of the line. The feed is introduced into the system by a loading hopper (2), generally located under a silo or a container; the material can be discharged at any desired location by holes placed in the bottom of the tube (4).

Any style of drop can be installed on the tube under the hole.

In special strong and resistant steel, they are characterized by a high quality of elasticity and flexibility.

Hardwearing and compact, they are constructed with a varnished galvanized steel plate casing or stainless steel, with direct or belt drive transmission.

- 1 way or 2 ways models, horizontal or with 30° inclination, in galvanized steel plate or stainless steel.

- Load hoppers, easily connected to the silo adaptor.

- Hoppers for restarting to cover long distances.

- Tandem hoppers to take feed from different silos.

Silo adaptors with shutter models Ø 440,540, 920; galvanized or stainless steel.

Plastic casing and metal shutter; remote control opening and closure; optional cover. Available tor pipe sizes Ø 60, 63, 75 and 90.

Thanks to the flexibility of the chain, spiral, and components, FALCON conveyor systems can easily handle long and winding routes, creating circuits with multiple changes in direction using just a single drive unit. During transport, friction is minimized, resulting in low power consumption. They are designed to ensure a clean working environment, free from dust dispersion, and require minimal maintenance, with quick and infrequent interventions, thereby reducing overall costs.

- Low maintenance costs, with quick and infrequent interventions.

- Efficient performance, high reliability, and reduced investment costs.

- Simple system design.