Bourgault Industries Ltd

MRB - Model III -Fertilizer Application System

The Mid Row Bander fertilizer application system provides optimal placement of nitrogen and sulphur fertilizer. MRBs maximize the benefits and reduce the risk of one-pass fertilizer placement, while establishing a high quality seedbed.

Most popular related searches

fertilizer application system

fertilizer applicator

fertilizer application

fertilizer

fertilizer placement

soil conditioning

seeding

coulter plow

fertilizer application optimization

tine

The MRB® III Fertilizer Applicator is the most advanced and durable mid row banding system offered by Bourgault.

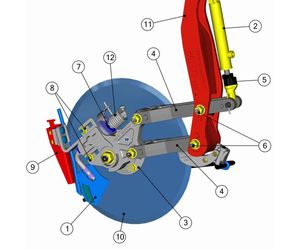

- Refer to this diagram of detailed information on the superior features designed into the MRB® III assembly.

- See more about the features & benefits of the Bourgault MRB System.

MRB® Settings & Adjustments - The key to trouble-free operation is correct depth setting and periodic greasing & adjustment.

-

Refer to a special video presentation which demonstrates these settings. MRB® III Settings & Adjustments Video

Momentary Isolation Switch - To further aid the ability to seed in wet conditions, the Momentary Isolation Switch option will momentarily lift the mid row openers to reduce draft long enough to get out of a sticky situation.

Closer Tine or Retaining Wheel Option - The outside closer tine or retaining wheel options are available for maintaining consistent soil retention over the furrow. Which option will work best for your operation?

Closer Tine or Retaining Wheel Option - The outside closer tine or retaining wheel options are available for maintaining consistent soil retention over the furrow. Which option will work best for your operation?

Mid Row Shank III - The MRS III fertilizer application system provides a viable option for producers that want to achieve optimal fertilizer placement with a simplified design. Producers are encouraged to compare the benefits of each fertilizer application system when considering which will work best for their operation.

The MRB® III fertilizer application system is the most advanced and durable mid row banding system offered by Bourgault. The extensive use of well engineered cast components, convenient depth adjustment and hydraulic engagement control will mean more time for you in the field seeding, and less time spent adjusting or maintaining.

-

Floating Carbide Scraper – The floating inside scraper maintains a good furrow in a wide range of seeding conditions.

-

Hydraulic Actuation – The hydraulically controlled Mid Row Bander® applicators are synchronized with the seed arms or shanks for efficient in-field operation.

-

Double-Tapered Roller Bearing Hub – You can expect a long service life with the high capacity hub and spindle assembly.

-

Parallel Link Arrangement – The MRB® body is mounted on parallel arms for a constant disc attack angle and seed boot / liquid tube orientation regardless of its operating depth.

-

Simple Depth Adjustment – Shims on the hydraulic cylinder are used for setting the depth.

-

Hardy Coulter Arm Pivots – The MRB® arm pivots are equipped with needle bearings and grease-able pins for long service life.

-

Fine Scraper Position Adjust (Behind Cast Mount) – The position of the scraper relative to the edge of the disc can be adjusted in fine increments.

-

Coarse Scraper Position Adjust – Adjust the whole scraper/boot assembly to maintain the optimal scraper-to-disc position as the disc wears.

-

Combo-Boot – The versatile combo-boot allows you to select between dry, liquid, or anhydrous forms of nitrogen application.

- Long Wearing Coulter – The large single bevel boron steel coulter is set to open the soil just enough to deposit the fertilizer.

- Scraper Pressure Adjustment - the pressure of the carbide scraper on the disk can be easily set to match soil conditions for optimal results.

- Strong & Durable Cast Components - the MRB III operates in the most challening agricultural environments without breaking or bending. Well designed castings are machined to exact specifications.