FG Pumps - Model FGM Series -Mechanical Diaphragm Pumps for Agriculture

The FG PUMPS FGAA series are mechanically actuated diaphragm dosing pumps for dosing liquids. Easy to use with minimum maintenance, FGM series are built following high qualify standard. The medium to be pumped is separated from the drive by a diaphragm. This is thus protected from damaging influences of the medium Safe, no external moving parts and leak free operations. Wide range of flowrate, up to 1000 liters for hour and pressure up to 14 bar. Accuracy +/- 2% from 10% to 100% of nominal flow. Standard micrometric manual adjustment, 1 mm per turn. 0-100% of adjustment while running or steady. Electric actuator or inverter on board optional.

- Leak-free

- Low and simple maintenance

- Long diaphragm service lives

- Linear control characteristics

- New innovative materials

- Standard high quality Italian brand

- 0.18Kw - 0.37Kw - 0.55 Kw 3Ph, 230/480 V, 50/60 Hz.

- 0.37Kw 1Ph 230 V, 50 Hz

- Optional: Eex-d, brushless, servoventilated, tropicalised. Nema flange and coupling available.

- Water treatment

- Waste water treatment

- Beverage industry

- Food industry

- Pulp and paper industry

- Fertirrigation / Sewaging

- Desalination plants

- Inverter on board with digital and analog inputs and outputs and Modbus communications for standard

Materials

The high quality of the materials guarantees reliable continuous operation. The optimum material is available for every requirement.

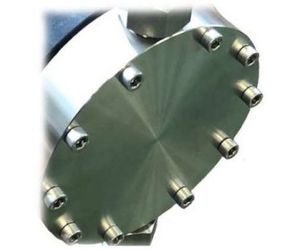

Pump Body Materials

FG PUMPS introduces, for his FGM series up to 250 L/h, a new material concept, specifically designed to replace aluminum without departing from its strength characteristics. The new "TECH" material is as strong and durable as aluminum but lighter.

Aluminum pump body for high flowrate up to 2000 L/h.

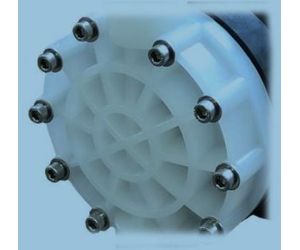

Pump-Head Materials

- PP reinforced, pure PVDF and S.S.316L as standard pump-head materials.

- PTFE, PVC, TITANIUM, and others materials available on request.

Diaphragm Materials

- PTFE coated.

Valve Balls Materials

- PYREX PTFE S.S.316L CERAMIC Standard Valve Balls.

Valve Seals Materials

- FPM. EPDM. PTFE standard valve seals.

Drive Unit

- The drive unit in each pump consist of a proven motor make, coupled with a stroke gearing in a robust case.

- The standard motors assembled on the pumps are 3Ph 0.18 Kw, 0.37 Kw and 0.55 Kw power.

- It`s possible to change the flowrate by acting on the manual micrometric adjustment, or by connecting a special signal that varies the motor frequency.

Special Version

We provide the individual solution for special dosing needs: solutions for viscous products, delivery valve with spring load, double valves, pump-head in non-standard materials with a customizable internal measures, pumps assembled on tanks, and many others.

Accessories

necessary accessories parts for the optimal installation of dosing pumps, such as pressure relief valves, backpressure valves, foot filter valves, pulsation dampers, dosing tanks can be ordered from us.

FGM With Polypropylene Pump Head

Ideal for:

- Water & waste water treatment (sulfuric acid, aluminum polychloride, sodium hypochlorite)

- Fertirrigation

- Pulp & paper industry

- Acid or neutral chemical products

Ideal for:

- Water & waste water treatment (fluorides, chrome, sodium hypochlorite)

- Neutral chemical products

- Acid or strong acid chemical products

Ideal for:

- Beverage industry

- Water & waste water treatment (peracetic acid, polyelectrolyte, nitric acid)

- Food industry

- Alkali or neutral chemical products