- Home

- Companies

- Whooshh Innovations LLC

- Products

- Whooshh - Fish Handling System

Whooshh - Fish Handling System

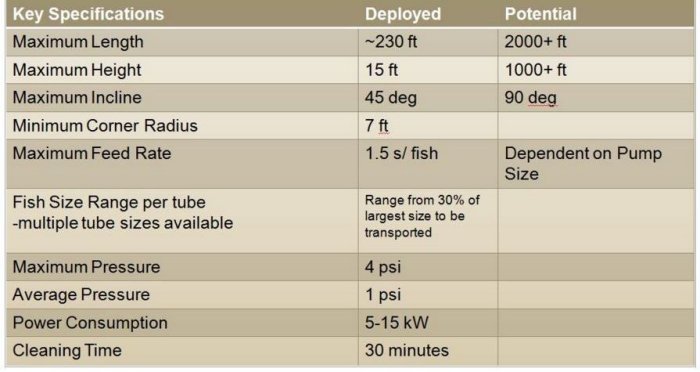

Automatic or Manual Feeding: High throughput, Feeds 40 fish per minute, Speed of 10 meters per second.

Easy to Install

- Flexible configurations

- Systems available up to 200 meters

- Custom-designed systems

Simple to Operate

- Efficient, gentle Hygienic

- FDA-certified materials

- Low maintenance

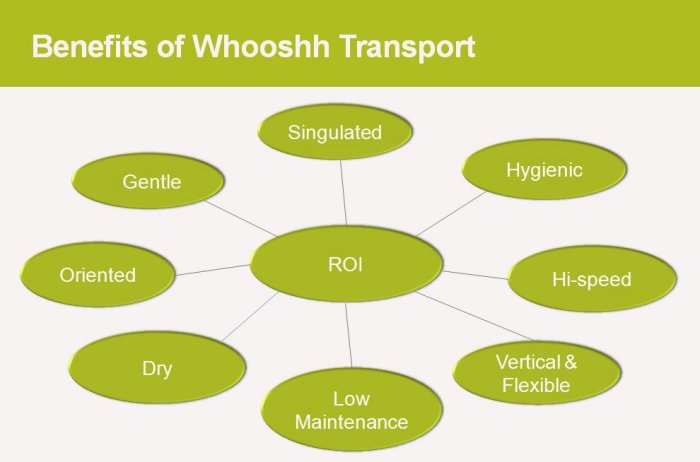

Overall Productivity and ROI

The Whooshh transport system is designed to improve product transport before it is packaged. Less wasted space, less wasted time, less wasted energy, and better quality and high value product yield. Replace expensive “hand carry” systems that utilize boxes/totes (and associated cleaning costs), pallets, ice, forklifts,and labor By reducing these wastes we increase your operational efficiency. Measurable metrics all improve, such as: energy consumption, labor use, product yield per square meter and per employee.

Simpler, gentler, and more hygienic product transport is now possible with Whooshh transport systems. We anticipate that our customers will realize a positive ROI in two years time or less – and in many cases much less. With Whoosh transport, set a new higher standard for quality, yield, and productivity. You can`t afford not to adopt, regardless of your previous capital investments.

Hygienic

Whooshh Systems are made with durable FDA approved materials capable of withstanding all standard cleaning agents including sodium hypochlorite, sodium hydroxide, hydrogen peroxide, bleach, chorine, UV, Ozone, and boiling water. CIP adaptation possible.

Standard cleaning time for entire system is approximately 30 minutes. Easily cleaned pump-houses contain the only movable parts – no removing conveyor belts or other large components. An added advantage over all other transport systems is the ability to completely dry the transport sleeve thereby reducing the chance of bacterial growth.

In comparison, conveyor belts systems are large and cumbersome and hard to clean. In many cases, it is not possible to thoroughly clean a conveyor because of the very large total surface area of the structure and many hidden surfaces. The result of the conveyor design is that plant and vessel operators must use considerable time and resources (labor and material) cleaning the systems – up to 1/3 of the processing plant time is used for cleaning every day.

Hi-speed

Each system is capable of handling the capacity of today`s processing machinery the product is being transported to – e.g. slaughter machine of 20 salmon per minute; heading machine 40 salmon per minute; filleting machine 30 salmon per minute. Optimize the processing line by incorporating our transport systems to avoid buffers such as holding tanks.

Up to 45 salmon per minute in each transport tube. Systems that transport larger numbers of smaller fish per minute are also available.

Gentle & Dry

In contrast to either conveyor belts or aqua pumps, the Whooshh transport system relies upon the creation of a seal around the fish and the introduction of a pressure differential which provides the motive force to the fish (movement). In particular, the Whooshh system provides for a soft, flexible sleeve that accommodates and gently and continuously engages the surface of the fish.

The Whooshh system does not move a column of water, it is for practical purposes a dry system. Because the Whooshh system relies almost entirely upon air (only a mist is introduced for lubricity) to create the pressure differential, the mode of force (movement) requires much less pressure and energy than traditional aqua pump systems. The Whooshh system is designed to provide transport of delicate objects (like fresh fruit and live fish) over distance without damage, bruising, or stress.

Flexible & Vertical

Transport along ceilings is easily accomplished. Take advantage of the “cheap real estate”overhead for the transport of products. Our transport systems are not constrained by traditional height limitations of fixed-in-place conveyor belts in processing plants and can be more easily moved or re-configured . No other transport method can provide the flexibility, ease of installation, and transport efficiency as our Whooshh transport systems. Customizable site specific flexible configurations available. Systems are easily installed and capable of transporting product up and over of other processing machinery.

We will work with you to help you determine the ROI of Whooshh transport within your operations. Each installation is different, but most applications have a return on investment of less than 2 years and sometime as few as 30 days.