- Home

- Companies

- Victor Pellet Mill

- Products

- Victor - Floating Fish Feed Pellet Mill ...

Victor - Floating Fish Feed Pellet Mill For Aquaculture

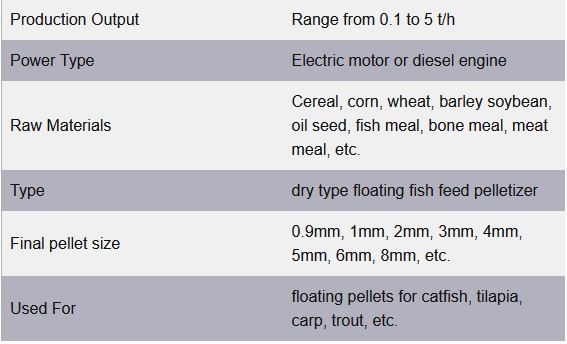

Floating fish feed pellet mill is a specialized machine for processing aquatic feed. It works by extruding raw materials like corn, soybean meal, fishmeal, and other minerals. This equipment produces aquaculture feed pellets that have stable buoyancy and settling properties. Because of the improved extrusion technology, fish feed processing efficiency can increase by 85% to 95%, and fish digestibility can improve by around 10% to 15%. This reduction in feed waste is significant. The floating fish feed pellet machine can adjust the final pellet size and hardness. It can also customize the nutritional content based on different growth stages, such as fry and adult fish. This customization helps ensure efficient fish growth and cost-effective feed use during aquaculture. The fish feed pelletizing equipment has become essential in modern fish feed processing. It boosts production capacity, ensures stable feed quality, and optimizes cost structure.

The core working principle of floating fish feed pellet making machine is the advanced extrusion technology. This technology uses high temperatures, high pressures, and high shear forces to puff and shape pelleted feed. The whole process is divided into the following main steps:

- Preparation and mixing of raw materials: After accurately weighing raw materials such as soybean meal, fish meal, corn meal, vitamins, and minerals based on the formulation, you need to mix them using a high-speed mixer to equalize the distribution of nutritional components.

- Feeding and conveying: The mixture is steadily fed into the extrusion chamber of the floating fish feed pellet mill through the feeder to maintain continuous and equal amount of feeding.

- Extrusion and shaping reactions: A screw propels the material at high speed, subjecting it to intense shear and frictional heating. According to industry data, the maturity level reaches 85%-95%.

- High temperature and high pressure treatment: The extrusion chamber temperature is usually over 100°C, which promotes complete gelatinization of starch, denaturation of proteins, and effectively inactivates pathogenic bacteria such as Salmonella.

- Expansion and forming: The material undergoes instantaneous decompression within the mold cavity, causing its internal moisture to evaporate and expand, forming a sponge-like structure.

- Granular cutting: The continuously extruded material is cut to a set length using a cutter to make the pellet size uniform.

- Drying/cooling: After reducing the moisture content to approximately 10-12% in a dryer, the structure is stabilized by cooling, and the product is finally transferred to the packaging process.