- Home

- Companies

- Zhangjiagang Micmachinery. Co.,Ltd

- Products

- Micmachinery - Model 3000BPH - Fully ...

Micmachinery - Model 3000BPH -Fully Automatic Fruit Juice Packing Machine

Designed primarily for packing plastic bags using suction nozzles, this machine is specifically suitable for filling and screwing caps on water agents and viscous materials. It features PLC programmable control with a user-friendly touch screen interface, enabling automatic filling and capping. The machine utilizes servo motor drive and double screw drive mechanisms to control the movement of the piston rod, ensuring stable filling with higher accuracy. Combining optical, mechanical, electrical, and gas components, it serves as an integrated filling and capping machine that offers convenient operation. With its reliable performance, high production efficiency, and strong adaptability, this machine guarantees stability throughout the operation.

The juice packing machine represents a significant technological advancement in beverage manufacturing, providing a streamlined and automated solution for efficiently packing juices. Meticulously engineered and designed, this state-of-the-art equipment seamlessly integrates various components to create a highly efficient packing line. By combining speed, accuracy, and reliability, the juice packing machine plays a crucial role in meeting the evolving demands of juice manufacturers.

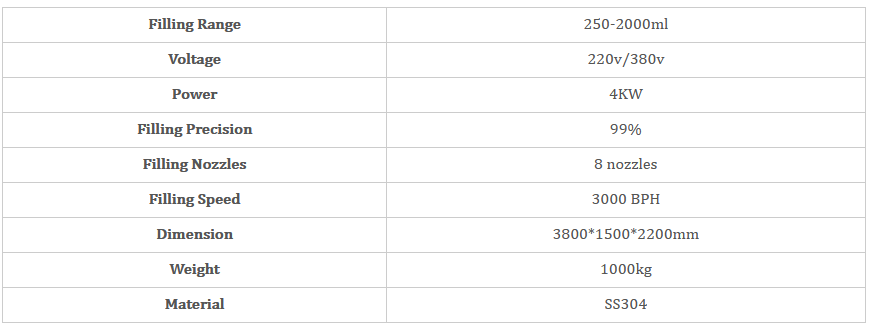

Micmachinery introduces the MIC Fully Automatic Fruit Juice Packing Machine, engineered to elevate your juice production efficiency. Designed for medium-scale manufacturers, this juice packing machine provides seamless integration into your production line, offering high-speed performance with a capacity of 3000 bottles per hour (BPH). With cutting-edge technology and precision engineering, our juice filling machine ensures superior quality and consistency in every bottle of fruit juice.

Why Choose the MIC Fully Automatic Fruit Juice Packing Machine?

1. Optimized Production Speeds

With a filling capacity of up to 3000 BPH, this juice packing machine allows for high-speed production, meeting the demands of expanding beverage companies. You can pack more products in less time, optimizing your operational output without compromising quality.

2. Precision Filling Technology

The juice filling machine incorporates state-of-the-art technology to provide accurate and consistent fills. Advanced sensors ensure that each bottle receives the exact amount of juice, preventing overfilling or underfilling, and reducing waste in the process.

3. User-Friendly Automation

The fully automated nature of the fruit juice packing machine reduces manual labor and minimizes human error. Its intuitive touchscreen interface makes it easy to monitor and adjust settings in real-time, providing your operators with full control over the entire packing process.

Key Features of the MIC Fully Automatic Fruit Juice Packing Machine

High-Speed Performance: With speeds of 3000 bottles per hour, this juice filling machine is designed for medium to large-scale production needs. It ensures fast, efficient packaging, meeting market demands while maintaining high-quality standards.

Flexible and Adaptable: Easily changeable to accommodate various bottle sizes, this fruit juice packing machine gives you the flexibility to offer different product formats. Whether you’re packing small or large bottles, changeovers are quick and hassle-free, allowing for minimal downtime during production.

Hygienic and Durable Design: Constructed with high-quality stainless steel, the juice packing machine is not only durable but also easy to clean. The hygienic design ensures compliance with stringent sanitation standards, preserving the quality of your product while ensuring that cleaning procedures are quick and efficient.

Energy-Efficient Operation: Designed with sustainability in mind, this juice filling machine minimizes energy consumption, lowering your operational costs while still delivering top-tier performance. This makes the machine a smart, cost-effective solution for your production line.

How the MIC Fully Automatic Fruit Juice Packing Machine Benefits Your Business

1. Increased Productivity

With its high-speed filling capacity, the juice filling machine boosts your production capabilities. The higher output means your business can meet the growing demand for your juice products, allowing you to scale up quickly without the need for major additional investment.

2. Enhanced Product Consistency

The automated filling system ensures uniformity in each bottle. Consistent fill levels across all batches improve the quality of your product, enhancing brand reputation and customer satisfaction.

3. Reduced Operational Costs

The fully automated system reduces the need for manual labor, cutting down on workforce requirements and minimizing the risk of human error. Its energy-efficient design also reduces power consumption, lowering your overall operating costs.

4. Streamlined Production Line

With its compact and versatile design, the fruit juice packing machine integrates seamlessly into existing production lines. It requires minimal floor space and can easily adapt to different production setups, making it an ideal solution for growing beverage companies looking to expand their capabilities.

Conclusion: A Smart Investment for Your Beverage Production

The MIC Fully Automatic Fruit Juice Packing Machine offers a reliable, high-performance solution for fruit juice manufacturers looking to enhance productivity while maintaining the highest standards of quality. Its efficient design, precision filling capabilities, and easy-to-use automation ensure that your production line runs smoothly, allowing you to focus on what matters most – producing premium fruit juice.

Get in Touch with Micmachinery Today!

Are you ready to improve your juice production process? Contact Micmachinery to learn more about how the MIC Fully Automatic Fruit Juice Packing Machine can help you meet your production goals and elevate your beverage business.

- The machine is equipped with PLC programmable control and a user-friendly touch screen interface.

- It enables automatic filling, cap loading, and capping.

- Utilizes servo motor drive and double screw rod drive to ensure stable filling with higher accuracy.

- The machine operates reliably, boasts high production efficiency, and demonstrates strong adaptability.