Gentle Roll By EBM Manufacturing

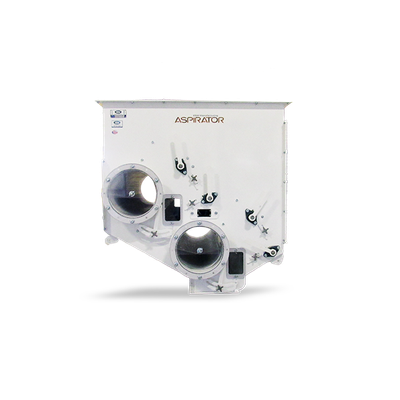

Gentle Roll - Model Aspirator -Grain Screening

The EBM Aspirator is engineered to efficiently remove lightweight materials such as dust, chaff, hulls, and bees wings from grains, using a single-pass, closed-circuit air system. Designed for small grains including rice, wheat, barley, and oats, this aspirator improves product quality by separating out foreign materials that have similar size and shape but differ in density from the desired product. The system allows air to flow through the product at a calculated rate, creating a vortex that separates unwanted particles, which are then collected through a bag filter or cyclone. Its versatility allows it to be used in conjunction with existing systems, including the Gentle Roll™, or as a stand-alone solution. The design allows for easy adjustment of airflow to suit different grain characteristics, ensuring optimal separation efficiency. With a compact footprint, it fits seamlessly into new or existing processing lines, delivering reliable performance and enhanced product purity.Most popular related searches

Barley

Popcorn

Wheat

Rice

Rye

Corn

Sorghum

Salt

EBM’s single-pass, closed-circuit Aspirator utilizes air to remove fines, dust, and lightweight material from good product. The EBM Aspirator allows air to pass through the product flow at a rate calculated to remove lightweight material.

As the air and product meet in the air pick-up zone, the air liftings separate and pull into the vortex, exiting to a bag filter or cyclone. The desired product is left to discharge out the hopper.