Crystal - Glass Cullet Optical Sorters

Crystal sorter is used for products particularly abrasive, for medium/large sized products, for frozen products or with specials characteristics.

In The Glass Recycling:

- Separation of ceramics, stones, metals, etc.

- Selection by colour of mixed glass.

- Selection for quality improving of glass from differentiated waste collection.

- Flakes selection of flat glass.

In The Minerals:

- Separation of impurities recognizables by a colour/transparency difference.

- Minerals selection for quality improving.

In The Chestnuts:

- Separation of spotted chestnuts or with defects recognizables by colour.

- Selection of fresh, frozen or dried chestnuts.

In Many Other Products:

Separation of non-conforming elements, spotted or with defects identifiables by colour.

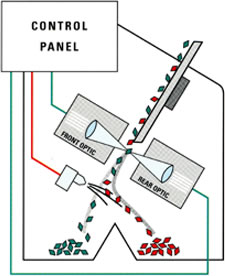

The sorting process of our CRYSTAL sorters is extremely simple: Through a vibrating feeder the product to sort is conveyed to the optical section where each single particle is scanned many times. The sensors convert the image into digital information. The relevant digital information is then compared to the data stored in the memory. Once the characteristics of the single analyzed element have been identified, a high precision ejector, shunts the non-conforming piece off to a reject hopper, whereas the "good" element is allowed to continue to the good product hopper.

Simplified handling: more than 35 years of experience in manufacturing color sorters and in the application of electronics to the separation technology have enabled SEA to reach outstanding results with its versatile and precise CRYSTAL sorting machines.

Versatility: thanks to microprocessors and to a sophisticated software, it is possible to make use of up to 30 different custom-made sorting programs.

Microprocessor Control: SEA color sorters are controlled by microprocessors allowing the use of specific functions such as the auto-diagnosis, the auto-setting, and the storage of the programs according to the specific production requirements. Very powerful microprocessors, together with the SEA-software and the special sensors, guarantee a perfect functioning ensuring the best results. CRYSTAL sorters are manufactured in stainless steel and anodized aluminum. The controls and fuse pannel are air- and water-tight and the operator has everything conveniently at hand. Inside the optical box, forced ventilation heaters and a thermostat control the temperature

Feeding: Specific feeding chutes or channels are used for different products in order to grant their best transport to the sorter`s detection unit. The loading hopper can be provided with minimum, medium and maximum level sensors controlling the vibrators` speed thus warranting the continuous stream of product into the machine

Automatic cleaning system: CRYSTAL sorters are featured by an automatic cleaning system inside the sealed optical box. A brush activated by a piston cleans the glass that protects the optical sensors: the continuous proper functioning of the machine is thus guaranteed.