Bintec - Grain Spreader

Evenly distributed and unmixed grain is the basis for safe storage. In order for grain to be safely stored in a silo without risking any loss of quality, even distribution and a homogeneous grain stock are absolutely essential. The Bintec grain spreader ensures that these requirements are met. During the harvest, batches with different levels of moisture are stored in even horizons.

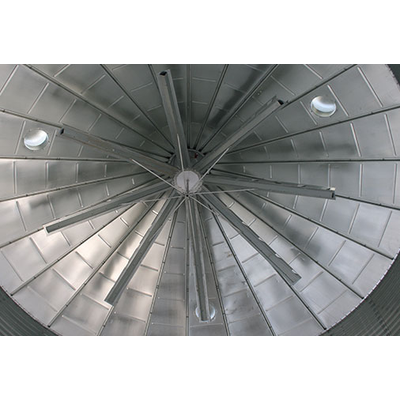

The key to success hangs under the roof.

The grain spreader is hung in the filling dome of the silo. It consists of the attached GrainFlow system, a firmly anchored distributor head and a lower rotating part with sheet metal channels, the chutes. When filling the silo, the grain first flows through the patented GrainFlow system. In this, the vertical crop flow is deflected into a rotating flow movement and then distributed evenly to the chutes by the distributor head. These are provided with small doors, which are opened more and more as you go down. In this way, a small part of the crop flow is diverted from each door.

This ensures that the grain is evenly distributed over the entire silo surface. Chaff and grain kernels are not separated by this "raining in". A compacted material cone in the middle of the silo and the formation of hot spots are thus reliably avoided.

Drive.

The distributor is driven solely by the flow of grain. The chutes are fitted with a uniform slight incline, which diverts minimally more grain on one side. This slight recoil is enough to spin the grain spreader at one to two revolutions per minute. This means that no external energy source is required for the drive or a controller.

Possibilities.

In combination with the grain spreader with ventilation fan, fully aerated floor and a storage management system from Bintec, safe cooling, ventilation and drying of grain in the silo is thus possible in a simple manner. And that with maximum efficiency and safety, with maximum protection of the grain.