- Home

- Companies

- BDP Industries

- Products

- In-Vessel Composting & Biodrying ...

In-Vessel Composting & Biodrying Systems

Agitated bay with forced aeration type technology for the toughest compost applications. Can accept the widest feedstock variations, requires the smallest system footprint and provides maximized odor capture and treatment capability.

Complete Turnkey Facility Scope

Services Provided:

- Total facility basic process design engineering including HVAC/odor control. (Detailed facility design engineering available from partner engineering firms)

- On Site Construction Review

- Start Up and Process Training

- Maintenance Contracts

- Facility Audits

- Privatized Operations (from partner companies)

BDP provides all of the basic process related equipment including:

- Compost agitator festoon system for power and control interface

- Compost aeration blowers, floor and embedded temperature sensors

- Compost moisture recovery and reuse system

- Compost facility HVAC system

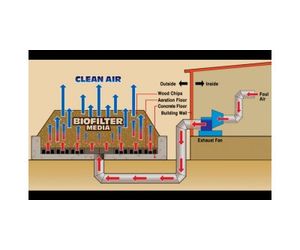

- Biofilter type odor control system (chemical odor control systems supplied as needed)

- Compost facility CompAer® process control system (For turnkey scopes BDP can provide all required equipment)

- Can handle any and all compostable materials

- Proven technology to decompose compostable plastics and other persistent compostables

- Smallest footprint of any compost system

- Low energy requirement

- Most uniform and stable compost product in the shortest time frame

- Complete containment of all odors

- Less operator labor than any other process

- Lowest capital cost of any enclosed agitated type composting system

- Total Facility Design Capability

Most Systems Offer One – BDP Offers All:

Continuous input from temperature sensors allows computer optimization of agitation/temperature/air flow/ and moisture to avoid hot spots and maintain ideal composting conditions so that a quality compost is consistently obtained in the shortest time.

Aeration can be positive or negative as shown:

Negative Aeration- Automated aeration

- Each zone independently controlled

- Major portion of process gases captured

- Reduced building ventilation requirements

- Leachate and condensate captured via air handling ducts

- Heat recovery/recycling for cold climates

- Ensures aerobic conditions maintained

- Automated aeration

- Each zone independently controlled

- No leachate or condensate formation

- Maximum drying ability

- Ensures aerobic conditions maintained

- Increases pile porosity to enhance convective drying ability and maintain aerobic conditions

- Exposes all portions of compost pile to the atmosphere over time thus enhancing convective drying

- Physical contact of drum tines reduces particle sizes, increasing surface area thus enhancing decomposition

- Remixes material such that microbial exposure to carbon and nutrient sources are maximized

- Translates material down length of bay eliminating need for loader movement

- The composting process drives off moisture – sometimes to the point of negative impact. If the compost becomes too dry, the microbes go dormant and the compost process shuts down until the moisture is reintroduced. Moisture addition also avoids an excessively dry and dusty end product.

- Animal Manures and Bedding

- Biosolids/WWTP Sludge

- Food Waste Waste/ Source Separated Organics

- Industrial Organic Waste

- Mechanical Biological Treatment

- Municipal Solid Waste

- Sludge Biodrying

- Wood Waste

- Yard and Green Waste

Automated Sorting:

Eliminates potential of inorganic contaminants in final compost

Mixing of Multiple Organic Streams:

Optimizes commencement of composting process

Bay Loading:

Eliminates the need for loading of bays manually with front end loader

Process Control:

Optimizes all compost related variables: moisture, aeration, agitation and temperature. Also provides for automated reporting for compliance

Agitator in Bay:

Daily agitation ensures highest quality compost end product in shortest period of time

Bay Unloading:

Eliminates the need for unloading of bays manually with front end loader

Screening:

Final compost refining step for premium grade compost quality