- Home

- Companies

- DT Food Machine

- Products

- DT Food - Industrial Tomato Paste ...

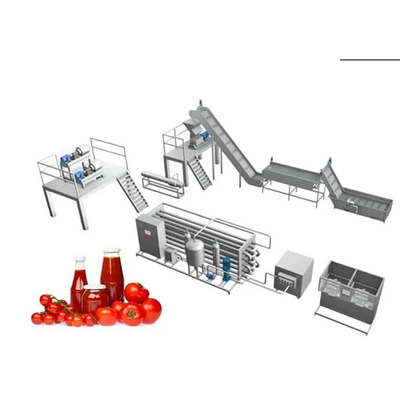

Tomato paste machine process fresh tomato tomato paste through main five systems into tomato paste. That is fresh tomato receiving, cleaning and sorting system, crushing and refining system, concentration system, sterilization system, and aseptic filling system.

End Product:Tomato paste 28-30% brix hot break & Tomato Paste 36-38% brix cold break

Package Type: Aseptic bags (5kg-1000kg), tin cans (100g-2500g),sachets (5g-100g), bottle and jars of various ranges.

Capacity: 2tons daily to 1500 tons daily.

Machine Material: Food grade 304 stainless steel/Stainless steel 316

The tomato paste production line process the raw materials fresh tomato into tomato paste (28-38% Brix). And the processing system includes equipment of raw materials air bubble washing machine, sorting machine, tomato crusher, storage tank, preheating machine, pulping and refining machine, concentration facilities, sterilization facilities, filling machine. While, the Package can be stand-up bag, metal can, PP container, bottle etc.

What is more, we can customize the tomato processing line to make tomato paste, tomato sauce, ketchup, tomato puree or tomato juice etc.

Tomato paste concentration rate: 28% brix, 30% brix, 32% brix, 36% brix ,38% brix.

Machine Materials: Food grade 304 / 316 stainless streel materials, best quality made

Capacity: 100KG/H to 1500KG/H (and customized)

Brand of Control and Electrical: The line is made of high quality and performance, supported by high class brand such as SIEMENS PLC, SCHNEIDER electronic parts, DANFOSS converter and other top brands.