- Home

- Companies

- Henan Lane Heavy Industry Machinery ...

- Products

- LANE - Model Liquid fertilizer plant - ...

LANE - Model Liquid fertilizer plant -Customized Production Line for sale

Lane launches a new organic liquid fertilizer production line capable of processing various organic raw materials to manufacture high-quality liquid fertilizers. Featuring fully automated production, we offer turnkey solution design and free quotes. Contact us now!

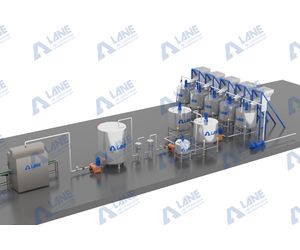

The LANE Liquid Fertilizer Production Line is a complete and highly integrated solution designed for the industrial production of various liquid fertilizers, including bio liquid fertilizer, amino acid liquid fertilizer, humic acid liquid fertilizer, water-soluble fertilizer, and foliar fertilizer.

This production line integrates raw material dissolution, chemical reaction, mixing, filtration, storage, and automatic filling into one continuous process. With a modular design and automated control system, it can be flexibly customized according to different formulas, production capacities, and plant layouts.

Applicable Liquid Fertilizer Types

Bio liquid fertilizer / Microbial liquid fertilizer

Amino acid liquid fertilizer

Humic acid liquid fertilizer (from lignite or weathered coal)

NPK liquid fertilizer

Liquid fertilizers with medium and trace elements

Foliar fertilizers and functional liquid fertilizers

Process Flow

Raw material feeding → Dissolution & mixing → Heating / chemical reaction → Homogenization → Filtration → Finished product storage → Automatic filling

Optional systems can be configured based on formula requirements:

Heating and insulation system

High-shear emulsification or homogenization system

Automatic batching and dosing system

PLC automatic control system

Main Equipment Configuration

Stainless steel dissolution tanks / reactor tanks

Liquid fertilizer mixing tanks (single-shaft or multi-shaft)

Metering pumps and pipeline system

Filtration system (bag filter or plate filter optional)

Finished product storage tanks

Automatic or semi-automatic filling machine

Electrical control system (PLC + touch screen)

All parts in contact with materials are made of stainless steel, ensuring excellent corrosion resistance, easy cleaning, and long service life.

Key Advantages

High formula adaptability for different liquid fertilizer products

High automation level, ensuring stable and consistent product quality

Flexible capacity configuration, from small pilot plants to large-scale production

Stable operation with low maintenance cost

Turnkey service from solution design to installation and commissioning

Application Scenarios

New or expanded liquid fertilizer production projects

Solid fertilizer manufacturers upgrading to liquid fertilizer production

Agricultural input factories and biotechnology companies

Overseas liquid fertilizer projects in Africa, the Middle East, Europe, and Asia