- Home

- Companies

- Changing Times LLC

- Products

- Changing Times - Model GPM - Liquid ...

Changing Times - Model GPM -Liquid Applicator

Pressure is adjusted by changing the position of the yellow valve handle that is located just above the pump motor. Changing the position of that valve setting will increase the volume of liquid returning to the tank and increase agitation in the tank thereby reducing the pressure or the inverse. The agitation decreases as the pressure increases. Operation in a range of 10 to 40 PSI will keep good agitation in the tank and produce even product flow.

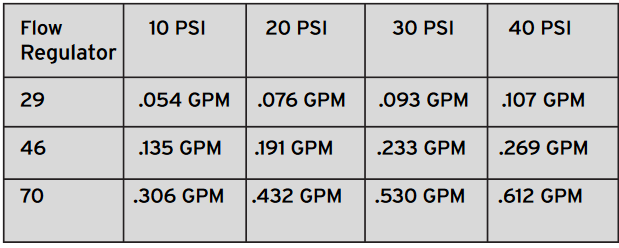

The Flow Regulator Disc sizes of 29 (installed), 46 and 70 (taped to tank) provide a range of application that should be adequate for most seed treatments and hay or silage inoculants. A fan nozzle may be added to the system if desired (not included) by adding below the Flow Regulator Body with a 1/4" pipe thread fitting and a nozzle body. It is suggested that the nozzle be sized slightly larger than the Flow Regulator and let the Flow Regulator do the work of managing the application pressure and flow. The hose length between the Flow Regulator Body and a Nozzle Body should be no more than 6 inches.

Dripping of product from Flow Regulator Disc body can be minimized by closing the 1/4" valve in the application line (Blue Handle).

Toggle switch will turn off the pump motor but will not stop drip from the Flow Regulator Body.

The yellow valve handle located below the 5 gallon tank can be opened to easily drain the contents of the tank.