- Home

- Companies

- MAKOBA GmbH & Co. KG

- Products

- Makoba MULTICRACKER - Model MC370 - ...

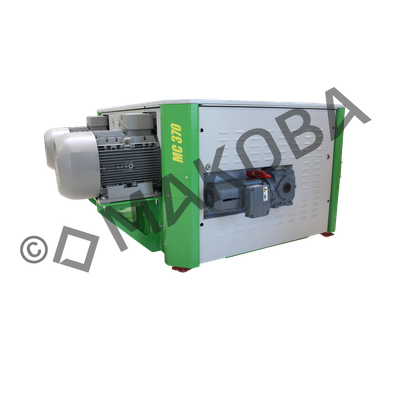

Makoba MULTICRACKER - Model MC370 -Universal Crusher

The MULTICRACKER MC370 is engineered for versatility and heightened performance across various industries, including animal feed and food & beverage. This machine delivers an efficient energy saving of 80%, primarily due to its innovative design and special cracker unit equipped with proprietary cracker disks. Its standardized construction reflects high German engineering standards. MAKOBA, a young mechanical engineering firm based in Southern Germany, excels in developing, manufacturing, and servicing machines tailored for the animal feed, food, and chemical sectors. Known for precision and efficiency, MULTICRACKER® delivers increased throughput and performance tailored to sectors demanding high capacity, further reinforcing MAKOBA’s reputation as a global player in crushing technology.

The universal crusher for various applications with increased performance

The MULTICRACKER® MC370 is suitable for a wide range of applications with a higher capacity demand e.g. in the animal feed industry or for applications in the food & beverage industry with a higher performance and throughput demand.

- Throughput: Up to 37 metric tons per hour (depending on material and grinding gap)

- Outer dimensions: 1638 x 1547 x 835 mm / 64,5 x 61 x 33 inches (L x W x H),

- Weight: 1300 kg / 2.889 lb

- Drive power: 2x 18,5 kW / 2x 25 HP (Horse Power)

- More details in the datasheet

- Crackerdisks resharpenable

- Crackerdisk profile of your choice (fine - medium coarse - coarse)

- Enclosed grinding unit

- Machine certified for ATEX zone 21/22

- Motorized, stepless adjustment of the grinding gap for Atex zone 22

- Adjustable, vibration damping machine shoes

- Bearing temperature sensors certified for ATEX zone 20

- Drive motors with NEMA Premium certification and various protection classes (IP5x/IP6x)

- TWIN version for two-stage grinding

- Inlet/outlet chute sizes according to your specifications.

- Destoner