Carrier Europe S.A.

- Home

- Companies

- Carrier Europe S.A.

- Products

- Carrier - Media Slurry Dryer

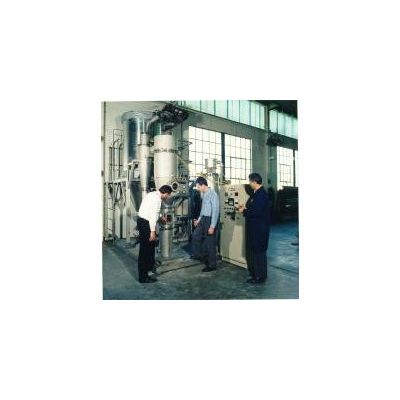

Carrier - Media Slurry Dryer

Our media slurry dryer is a cost-effective drying method for the production of super fine powders from liquid phase reaction or wet grinding operations.

Most popular related searches

With a compact design and efficient operations, our slurry dryer systems allow high viscosity materials to be pumped directly into dryer without mixing or atomization.

Slurry dryer raw material applications include:

- Abrasives

- Alumina

- Hydroxide

- Barium sulfate & barium titanate

- Bentonite

- Calcium carbonate & calcium phosphate

- Carbon black

- Chrome oxide

- Dyes & pigments

- Ferrite

- Kaolin

- Metal powders

- PVC emulsion

- Silicon resin & styrene resin

- Talc

- Titanium oxide

- Zircona

- Compact unit, space-saving construction.

- Uniform distribution of slurry.

- High heat capacity coefficients.

- Accelerated drying time for large capacities.

- No atomizer required.

- Agglomeration prevented (no milling required).

- Selection based on product character.

- Effective distribution of air flow.

- Continuous, dependable operation.

- Easy inspection and maintenance.

- Fuel consumption savings – up to 30 percent.

- Furnished through a license agreement with NARA Machinery Company, Ltd., Japan — a world-class leader in Fluidized Bed technology.