NHM Limited

- Home

- Companies

- NHM Limited

- Products

- NHM - Model MILKPACK Series 1500 - Milk ...

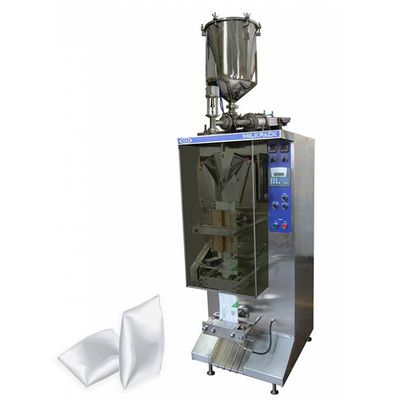

NHM - Model MILKPACK Series 1500 -Milk Pouch Packing Machine

FromNHM Limited

MILKPACK series packaging machines are used for packing of liquid and viscous products in polyethylene "pillow" pouch. The main purpose of MILKPAK machines is the filling and packaging of milk and dairy products, mayonnaise in PE "pillow" pouch. These machines belong to the latest generation of packaging equipment and are developed for stable and reliable operation. MILKPACK machines are highly automated and demonstrate high productivity. MILKPACK 1500 is a mechanical single head machine. Products to be packed: Milk, kefir, sour cream, sauces, mayonaisse, etc.

Most popular related searches

- PRODUCTIVITY: 1500 pouches/hour

- FILLING RANGE: 200 - 1000 ml

- POWER SUPPLY, MAX: 220/380 V, 50 Hz, 2.3 kW

- COMPRESSED AIR PRESSURE: 5 kg/cm2

- AIR CONSUMPTION: ~ 0.2 m3/hour @4 bar

- PACKAGING MATERIAL: 1/2/3-layered polyethylene film with black internal layer;

- thickness – 70-90 microns, width – 320 mm

- FILLING ACCURACY: ± 0,5-1% [depending upon bulk density of product, constant product level in the product tank (for liquids), proper maintenance]

- OVERALL DIMENSIONS , (WxLxH): 750 x 900x 2675 mm

- WEIGHT, NET: ~ 450 kg

- Complete sanitary design - Machine body and all frames made of Stainless steel. Doors for safety of operators

- UV lamp for film sterilization - included in standard machine

- Controls - Programmable logic controller (PLC) ensures smooth functioning of machine & ease of operations

- Self diagonistics - all emergency warnings displayed on screen that reduces downtime during trouble shooting

- Pneumatic components - Festo (Germany) & Camozzi (Italy)

- CIP cleaning - 2 programs for connecting machine to centralized CIP system at dairy as well for autonomous cleaning of machine

- Photoeye mark sensor & thermal printer - included in standard machine

- Filler - liquid or universal piston filler for packing a wide range of products

- Product tank fitted with level sensor, infeed pneumatic valve and spary ball for cleaning of tank

- Outfeed conveyor for filled packets

- Autonomous CIP system