- Home

- Companies

- Mobile Manufacturing Company

- Products

- Mobile Dimension Saw

Mobile Dimension Saw

The Mobile Dimension Saw turns logs into lumber by traveling through the log rather than the log traveling through the saw. Once the log is in position the log doesn’t need to be moved or turned to be completely sawed. The log can be moved to obtain larger sizes or special shapes that cannot be obtained between the sawblades. Turning the log can make special projects of larger size such as tabletops, fireplace mantels, doors, diving boards and unique grain cuts. Three circular saw blades - one vertical, two horizontal - saw the width, depth and length dimensions simultaneously. The three blades allow logs of any diameter to be completely sawed with minimum edgings and slabs. And accuracy is assured because each piece of lumber is completely sawed in a single pass. From the first cut to the final timber, each piece of lumber is precision-cut, then powered back to the operator for easy handling. No rehandling or resawing is required.

And the operator remains in one position - at the head of the sawmill, controlling the complete operation and the size of lumber being cut. With the Mobile Dimension Saw, you get maximum production with minimum effort.

A Detailed View of the Mobile Dimension Saw

The Mobile Dimension Saw will saw any size lumber up to 4-1/4`` (107.9 mm) by 12-1/4`` (311 mm) with the double edger saw and 8-1/4`` (210 mm) by 12-1/4`` (311 mm) with the single edger saw being used.

- Dimensional accuracy to plus or minus 1/32`` (.79 mm) is achieved because each length of lumber is completely sawed in a single pass. Two edger blades saw one or two lengths of lumber per pass.

- mobile sawmillThe top edger saw is positioned accurately to 1/32`` (.79 mm) quickly and easily by the edger control and dial with calibration ring.

- mobile portable sawmillAdding a third edger blade lets you saw up to three pieces of lumber in a single pass. Additional edger blades (a minimum 2-inch (50 mm) spacing on the edger shaft) may be added for cutting multiple dimension lumber.

- portable mobile sawmillFor lumber larger than 4-1/4`` (107.9 mm) in width the bottom edger saw is changed to a 19-1/2`` (495 mm) saw blade to give you up to 8-1/4`` (311 mm) lumber. The top edger saw is moved up and out of the cutting operation.

- american made portable sawmillThe horizontal dimension of the lumber, when using the board & block system, is determined by the horizontal movement of the sawmill. The movement of the sawmill is controlled by two gauges that make positive contact with the log.

- mobile portable sawmillThe horizontal dimension of the lumber using the end stand set up is by a rack and pinion gear controlled by a dial that registers the amount of the distance moved.

- mobile portable sawmillAn offset control is used to adjust the sawmill to the log position and to the taper of the log.

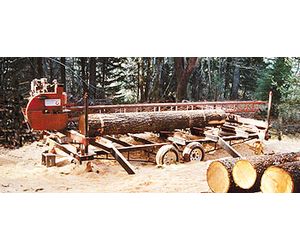

Mobile Manufacturing Company’s telescoping Mobile Trailer offers the optimum in productivity and operating ease. With the Mobile Trailer you arrive at the sawing site completely set up and ready to operate. With it’s eight-foot width and telescoping side channels, the Mobile Trailer meets all legal requirements for highway towing. Once you reach your cutting site, the side channels can be lengthened if you want to saw logs longer than 20 feet (6.09 m) in length. The side channels are quickly and easily telescoped in length, if necessary, allowing you to saw logs up to 26 feet (7.9 m) in length. If the logs are 20 feet (6.09 m) and shorter, then leave them at the towing length and lower the stabilizer jacks. This lets you quickly level all corners and sides, so you’re set up and in production in a matter of minutes.

The Mobile Trailer is designed and constructed with the same meticulous craftsmanship that is evident in the Mobile Dimension Saw. The heavy-gauge steel frame features rigid, lightweight cantilever construction. Fifteen-inch tires and tandem wheels with spring supported axles make towing very stable and easy.

The Mobile Trailer is completely wired with running and license plate lights as well as tail, turn and brake lights. Optional features include electric brakes (required in some areas), and a battery-powered winch attachment for log loading. Nut and bolt construction allows for easy disassembly and reassembly when crated for shipping.

- Endstands allow the operator to quickly and accurately raise and lower all four corners of the sawmill from the operator`s position.

- Log Loading Ramp allows easy and fast loading of the logs onto the cutting surface.

- Log Holders securely holds log or multiple logs in sawing position. Once in place the log is completely sawed without moving or turning.

- Adjustable Jacks for quick leveling and stabilizing of the mobile trailer.

- 2-inch Ball Coupler with safety chains for safe, easy towing.

- Rack and Pinion Crossbeam precisely supports the sawmill for accurate horizontal movement.

- Rack and Pinion Shoe positions the sawmill in the horizontal direction.

- Main Saw Blade, 30 inches (762 mm) in diameter, designed and manufactured by Mobile Manufacturing Company to exacting standards. Different sawblades are available, varying in the number and width of teeth, optimized not only for the different available power sources but also for the different species of logs you want to saw.

- Edger Blades, 11-1/2 inches (29.1 mm) in diameter also designed and manufactured by Mobile Manufacturing Company. Different sawblades are available, varying in the number and width of teeth. The lower blade remains stationary, while the upper blade is adjusted vertically to cut the desired depth dimension. A third edger blade may be added when cutting smaller dimensions for even greater production per man hour. A 19-1/2 inch (495 mm) sawblade that comes with the model 128 is exchanged with the 11-1/2 inch (29.1 mm) sawblade to allow larger dimensions up to 8-1/4 inch (210 mm) to be sawed from the log.

- Tandem axles allows easy and stable towing and fast setup.

- Rigid Steel Track provides maximum strength and stability as it carries the saw through the log. Two 10-foot (3.05 m) track sections and one 4-foot (1.22 m) are standard with the trailer that allows cutting of logs up to 20 feet 4 inches (6.2 m). Track sections can be added to sawmills not on trailers to saw logs up to 60 feet (18 m) in length.

- Telescoping Side Channels extend the trailer log cutting length to 26 feet 4 inches (8.03 m). An additional 6-foot (1.83 m) track section will need to be added.

- Adjustable Torsion Bars keep the trailer stable and squarely positioned at all times.

- Log Loading Winch with DC electric motor and worm gear drive allows easy loading of logs onto trailer.

- Battery Box enclosed for protection and transport of two 12 volt DC batteries.

- Reversible-Drive Motor Lift raises and lowers the sawmill on the endstands.

- Rack and Pinion Dial allows the operator to precisely gauge the horizontal dimension of each cut.

- Engine (or optional electric motors), available in a variety of horsepower ratings. Modified to provide maximum power under adverse operating conditions. Easily removed and reinstalled for easy transport and handing.

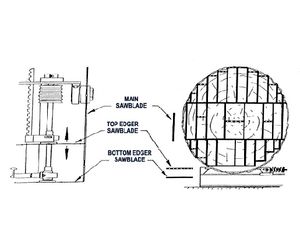

The following shows one way of sawing a log into lumber. The vertical line in the illustration shows the main sawblade cuts while the solid horizontal line shows the bottom edger sawblade cuts. The dotted horizontal line shows the saw cut of the top edger sawblade.

The Mobile Dimension Saw is positioned both vertically and horizontally by the operator by calibrated controls. The positioning can be changed at any time to obtain the sizes of lumber desired and obtain maximum lumber recovery from the log. The vertical position will determine the width dimension of the lumber. The horizontal position will dertermine the thickness of the lumber. The vertical dimension of the lumber (width) can be as large as 12-1/4" (310mm). The horizontal dimension of the lumber (thickness) can be as large as 8-1/4" (210mm) for the Model 128. These larger cuts are obtained by using the large single edger sawblade. The above models and Model 12 can saw lumber with the double edger sawblades as thick as 4-1/4" (110mm).

The 24" (600mm) diameter log illustrated above describes a random sawing operation. The log diameter could be any size as the Mobile Dimension Saw is unlimited to the size of the log that can be sawed. We are only showing one way of sawing the log. Both vertical and horizontal dimensions as well as the adjustable top edger sawblade could be changed in an infinite number of ways to completely saw the log into the desired sizes of lumber. The log is held in position by log holders under the log.

Power Options

Gasoline Engine

- Gasoline-powered Volkswagen engine assembled by Mobile Manufacturing Company using specially modified and original parts.

- Air-cooled, 4 cylinder, 4 cycle, governor, throttle, choke, oil temperature and pressure gauges, fuel pump, fuel filter and fuel tank.

- Battery key start, distributor, alternator and hour meter.

- Weight: 270 lbs. (122.7 kg)

- Two power units available: 1700cc (57hp) 1835cc (67hp)

- Engine Fuel: regular, premium grade, leaded or unleaded gasoline.

Electric Motors

- Fully enclosed 25 hp and 15 hp, aluminum frame 230/460 volt, 60 cycle, three phase with electrical motor control panel, start-stop and safety switches, control and power wiring. (Other voltage and cycle ratings also available.)

- Weight: 550 lbs. (250 kg)

Electric powered model

- The double electric motors obtain a horsepower rating much higher than there 25hp & 15hp. The duty cycle of the sawing operation allows these motors to develop 4 times their constant horsepower ratings. The 25hp motor becomes 100hp and the 15hp become 60hp. The included control panel allows the motors to obtain this higher horsepower output while still protecting them from overheating. The electric sawmill is built stronger and has more teeth in the sawblades to allow faster sawing speeds and more production. The electric motors are aluminum frame so they are much lighter than cast iron motors.

Track

- Standard length included with all models: 20 feet (two 10 foot lengths) (6.096 m).

- Weight: 380 lbs. (173 kg)

- Sawing length 16` 4`` (4.98 m)

Additional Track Lengths

- 4 ft. (1.22 m): 85 lbs. (39 kg)

- 6 ft. (1.83 m): 125 lbs. (57 kg)

- 10 ft. (3.05 m): 190 lbs. (86 kg)

Feed Control

- Hydrostatic: All models and power options.

- Operator controls feedrate and direction with automatic reverse at far end and neutral at head end.

- Saw teeth require resharping approximately every 1,000-3,000 bd. ft. (2.2-6.6 m3); replacement every 30,000-50,000 bd. ft. (66.6-111.1 m3).

Model 12XLS

- Double edger saws permit either one or two pieces of lumber to be cut simultaneously.

Maximum Cut

- 4-1/4`` x 12-1/4`` (107.9 mm x311 mm)

Minimum Cut

- 1/8`` x 1/4`` (3.18 mm x 6.35 mm)

Main Saw Blade

- Diameter: 30`` (762 mm)

- Kerf: 5/16`` (7.94 mm)

- Optional 1/4`` (6.35 mm)

Edger Saw Blade (2)

- Diameter: 11-1/2`` (29.1 mm)

- Kerf: 1/4`` (6.35 mm)

- Carriage Weight: 230 lbs. (104.5 kg)

Cutting Cycle

- 15 - 90 seconds, 16-foot (4.88m) log. Average production, one man, per day: 1,500-5,000 bd. ft.(3.5-14m3)

Model 128

- The Model 128 can be operated as either a double edger sawmill or as a single edger sawmill. When operated as a double edger sawmill the specifications are the same as the Model 12XLS. The Model 128 can be quickly converted to single edger operation by replacing the 11-1/2`` (292.1 mm) bottom edger with a 19-1/2`` (495 mm) edger blade. (Production is increased beyond that of the double edger set-up, when lumber of larger dimensions than the double edger set-up can saw are, produced.)

Maximum Cut: Single Edger

- 8-1/4`` x 12-1/4`` (210 x 311 mm)

Single Edger Sawblade

- Diameter: 19-1/2`` (495 mm)

- Kerf: 5/16`` (7.94 mm)

- Optional 1/4`` (6.35 mm)

Main and Double Edger Sawblades

- Same as Model 12XLS

Select the Sawing Method to Fit Your Operation

The portability and versatile design of the Mobile Dimension Saw make it adaptable to virtually any work site. And, it gives you a choice: take the sawmill to the log, or bring the log to the sawmill. With the Mobile Dimension Saw you have a choice: you can choose one or the other or both.

The Standard Sawmill Using the Board and Block Method of Operation

The standard sawmill, with its detachable two-wheel trailer is ideal for use in hard-to-get-to or environmentally sensitive areas; in locations where the logs are too scattered or too large to be easily moved; or when no log handling equipment is available or able to move the logs.

This forest giant that is over 9 feet (2.75 m) in diameter has been set up with the board and block method. The light end of the sawmill has been placed on the set up board and the saw engine is powering the saw carriage up the track to the saw starting point.

The positioning of the sawmill was easy because the engine and saw carriage provided the counter-weight to lift the opposite end of the track onto the log. Each set-up board position determines the height of the sawed lumber. The saw will cut the log by moving across the board. It will then be lowered to the next board to continue the sawing operation.

Standard Sawmill Operation

The standard sawmill is quickly and easily moved from log to log with the small two-wheeled trailer. It can be moved by any motor device or by one person.

The log is prepared by simply stacking boards and spacer blocks at each end of the log. Different dimensions are obtained by various size spacer blocks. The boards are attached to the log with lag bolts. The special tools to set up the board and block method of sawing are included with the saw.

Once the board and block frame is completed, one man can easily position the track on the board.

The engine and saw carriage is transferred to the starting end of the track. The weight of the two units will now counterweight the track weight.

The track is now easily lifted by one man and placed on the other end of the framework.

The sawmill has been transferred from the trailer to the log and is ready to saw the complete log. Once the log has been sawed the sawmill can be transferred back to the trailer by reversing the sequence.

The Endstand Option

To increase production - and simplify operations - Mobile Manufacturing Company also offers endstands that allow the operator to raise and lower all four corners of the sawmill at one time - from the operator’s position at the head of the saw - without constructing a board-and-block framework. The smaller diameter of trees in many regions today results in a majority of our customers utilizing this system.

Available with either a hand crank or an efficient motorized control system, endstands can be raised and lowered quickly and easily.

Endstands are available in a variety of heights to accommodate logs of any diameter. Endstands can be mounted on a framework constructed at your cutting site, installed on a trailer you build yourself, or placed on a portable endstand trailer built by Mobile Manufacturing Co.

The Mobile Dimension Saw delivers all the power you need.

The Mobile Dimension Saw offers two different power options to fit different sawing requirements. The power unit recommended will depend on a number of factors - log species, climate, altitude at the cutting site, dimensions being cut and level of production desired. A 57-horsepower Volkswagen engine - modified to reduce weight and improve performance in adverse operating environments - is standard equipment on the Mobile Dimension Saw. This lightweight yet powerful economical gasoline engine is also available in a 67-horsepower model. All engines are completely assembled in our own plant and modified using purchased original equipment parts and parts manufactured by Mobile Manufacturing Company. In thousands of hours of operation in every kind of climate, these engines have proven to be exceedingly reliable, requiring only routine maintenance and minimal care.

Extensive modification to the cooling, fuel system and crankshaft provide unmatched reliability and economy in even the harshest environments. One gallon (3.7 L) of regular gasoline cuts from 500 to 2000 board feet (1.2 to 4.8 m3) of lumber depending on the species and dimensions being sawed. The gasoline engine is easily removed and reinstalled on the sawmill, so it can be used to power other equipment such as planers, table saws, pumps or electric power generators. These engines are equipped with U.S. Forest Service-approved spark arrestors and a detachable gas tank.

Electric Powered Mobile Dimension Saw

The Mobile Dimension Saw is also available with electric motors. For operations that have adequate electric power available and equipment to deliver the logs to the cutting site, the electric powered model is the saw to use. Assuming other factors - dimensions cut, log species, and operator efficiency - remain the same, the electric powered Mobile Dimension Saw is capable of producing up to 3 times the lumber produced by the gasoline powered models. Each saw shaft is powered by it’s own motor. The main saw by a 25 hp motor and the edger saws by a 15 hp motor. The work cycle of the sawing operation allows these motors to perform at three times their rated horsepower. Maintenance requirements for electric motors are minimal. So if you intend to install a Mobile Dimension Saw at a permanent site with access to electric power or if you have a generator, consider the electric motor option. It will pay off in greater production, low maintenance and lower operating costs.

Electric Sawmills can be set up in one location with commercial power or can remain portable and use a generator. All Mobile Dimension Saw models come with two main guard saw dust discharge chutes.

Hydrostatic feed control

The operator has complete control of the Mobile Dimension Saw throughout the sawing sequence. The variable-speed hydrostatic controls give the operator positive, fingertip control of the complete sawing cycle from a stationary position at the head of the saw. The forward-neutral-reverse movement and fast-to-slow feed rate may be changed at any time and as often as you wish. So you can move into and out of knots, twisted wood grain, or from softwood to hardwood and still maintain optimum production.

Hydrostatic control provides more feed speed options with fewer moving parts involved in the feedworks system. The hydrostatic unit is sealed and self contained, and has an excellent record of giving years of dependable service with very little maintenance. This unit goes along with Mobile Dimension Saw’s modular construction practice that makes it extremely easy to field maintain and replace parts with little or no special training.