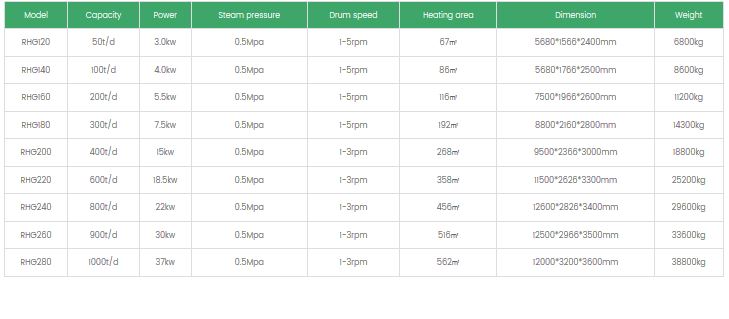

Model RHG -Softening Kettle

RHG softening kettle is rrciriy JSed for softening so^tean and rapeseed In the c*l leeching pretreatment process improving the plasticity of :he raw material SO that Ihe errtoryonic sheet rolled by the rolling mill is thin and not broken, thereby inproving

the steaming, pressing and leaching effects.

RHG horizontal drum softening machine is suitable for 50-1000 tons/day ofl mill and leaching oil plant It is mainly used for softening and drying raw materials. Improving the plasticity of raw materials, reducing the moisture of raw materials, and roling out the rollng mffl. The blank is thin and not broken, thereby in-proving the effects of steaming pressing and leaching. The aaVent of the RHG horizontal drum softening machine has filed the domestic gap and overcome the shortcomings of other softening equipment

- The rotation of the drum makes the material turn more evenly without dead angle, avoiding the phenomenon of material burnt caused by the dead angle of the layer softening pot ond the material softens evenly ond thoroughly;

- The energy consumption is gready reduced and the softening equipment of the same output the RHG honzontol drum softening machine is only one tenth of the installed capacity of the vertical softening pot which greatfy reduces the production cost

- The new softening pot has no scraper, which avoids the abrasion of the scraper and the heating layer, so the equipment has long service life, low failure rate and low maintenance cost

- The RHG horizontal drum softening machine Is made of the latest design, which mokes the material control extremely convenient Acccrding to the variety and nature of the materials, the speed of the drum softening pot is adjusted by the governor, and the softening time of the material In the softening pot con be flexibly adjusted:

- Due to its unique structure and careful design, the equipment can soften high moisture materials while the water removal rate of dry materials can reach 2%.