Demir Packing & Agricultural Machinery

- Home

- Companies

- Demir Packing & Agricultural Machinery

- Products

- Demir - Modular Packing Machine

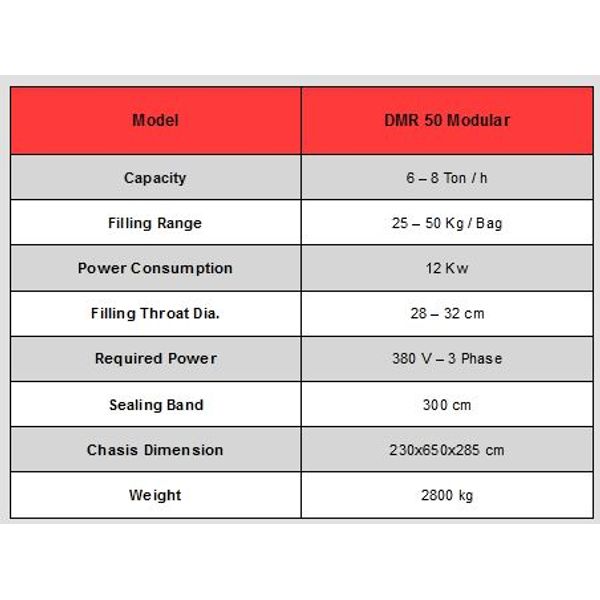

Demir - Modular Packing Machine

Best way to retain product freshness and preserve quality by packing harvested materials in a range of 25-50 kg bags and also other industrial products such as manure, fertilizer, bolt etc. Our machines not only provide a significant contribution in the feeding animals by preserving materials’ longtime freshness and productivity to the livestock sector but also decrease workload of industrial sectors. Machine has integrated bunker, conveyor and packing unit. You can use the closing with two system. System 1 has vacuum + press + hot sealing. System 2 has vacuum + clipping + sewing. Capacities can change up to materials to pack, target weight and closing system.Most popular related searches

manure fertilizer

livestock industry

tractor

fertilizer

harvesting system

livestock

animal feed

animal feeding

fertilizer machine

- 3 in 1 mobile concept (bunker + conveyor + packing unit) is economic and best solution.

- Entegrated loading bunker for direct loading from trailers, trucks, loaders and doesn’t require too much effort.

- Entegrated vertical conveyor band provides direct transfer of materials from the bunker to the intaker unit as synchronised working with motor drivers.

- Mobile main chasis with optimum dimension of complete set allows easy international freight in container for seaway.

- Accurate and fast weighing.

- Weighing and filling unit with movement sensor provides slowly and regular filling the materials and perceive the bags and move the bag holders, save from time.

- Strong press unit brings the packaged material’s smooth appearance, easy packing save from space.

- Strong air suction ability with vacuum unit, absorb the air inside the bag.

- Any kind of closing with : Hot sealing, sewing, clipping up to user demand can be entegrated.

- All system is operated by the electronic control panel or automation PLC.

- Air compressor supplies optimum air amount for all related units.

- Mechanical lift jack prevents any damage by stabilizing the machine.

Back Bunker

Materials can be load into the bunker by using tractor without any necessary of other heavy equipments. Folding sidewalls up to the road and working position. Synchronize working with machine. Automatic control and speed adjustable.