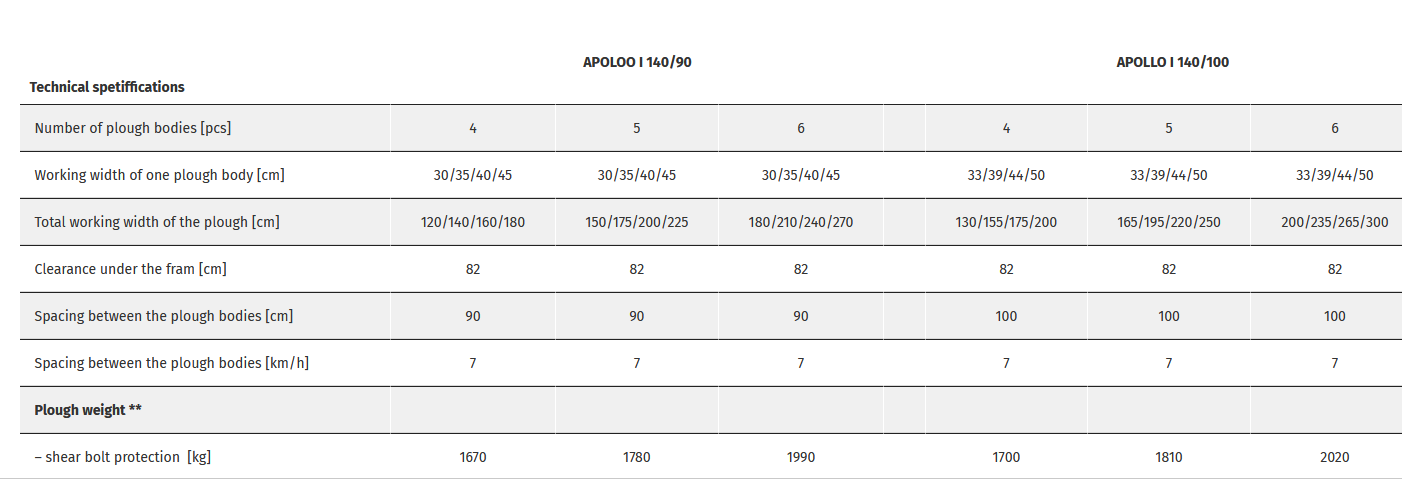

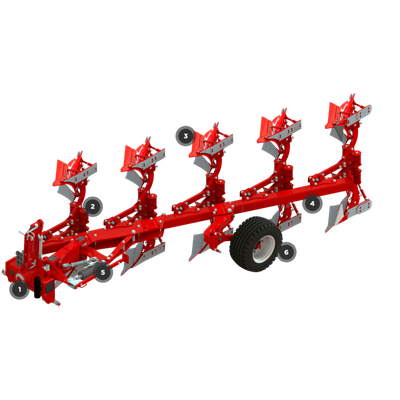

Opall - Model APOLLO I 140 -Mounted Plough

APOLLO I models are four- to six-plough bodied mounted reversible ploughs designed for tractors from 120 horsepower. Adjustment of plough bodies width is performed mechanically by changing the position of the plough body holder on the plough frame. The new in the plough section is the first generation APOLLO I mounted plough. It will satisfy customers who want a large mounted plough. It sells well due to its variability.

- Tradition of agricultural machinery production since 1995

- Disc harrows combine years of experience with the use of modern production technologies

- Precise processing to the smallest detailHigh-quality processing ensures your long-term satisfaction and precision work

- Prototype testing under the most demanding conditionsBefore launching into the market, the machine has been tested under the toughest conditions to develop a truly precise assistant for your farm

- Unique angle of disk positioningDisc positioning angle allows for higher work speed while maintaining low power consumption and excellent work quality

- Simple design without lubricating pointsThe machine is easy to maintain due to maintenance-free bearings

- Choice of three types of back-up rollersFor optimal work in your conditions, you can choose from tubular, flex or cracker rollers

- Maintenance-free bearings with perfect external protectionSuitably chosen shape and systematic arrangement of safety rings and caps ensures excellent protection against dust, dirt and mechanical damage and thus ensures long service life of all bearings of the machine

- Securing rubber cylinders secured against sliding outThe rubber cylinders are fixed mechanically in the unit with rubber stoppers

- We have our own production of wear partsWear parts made of special abrasion-resistant steel have a long service life

Due to its robustness, the machine is designed for higher power ranges tractors. A completely new frame concept gives the plough high rigidity and strength. Thanks to the possibility of choosing the type of machine in the range of 4-6 coulters, it covers a wide range of requirements of farmers who prefer ploughing with mounted ploughs. New construction elements are used on the APOLLO I machine. It will also satisfy customers who want a large mounted plough. It sells well due to variability. The best choice - utility value.

- Basic equipment

- Modular system 4+1, 5+1

- Mechanically adjustable width of the plough body

- 80 cm underframe clearance

- Plough bodies including trashboards

- Knife coulters on the last pair of plough bodies

- Protection by shear bolt / spring mechanism /hydropneumatic system

- Rear reflexive plates

- Suspension shaft cat. 3

- Frame profile 140 x 140 x 10 mm

- Combined wheel APOLLO I

- Memory cylinder APOLLO I

- Skimmers

- Disc coulters

- Floation tyre 13.0/55-16