- Home

- Companies

- N. BLOSI Manufacturers of Agricultural ...

- Products

- N. Blosi - Model Senior - Moving ...

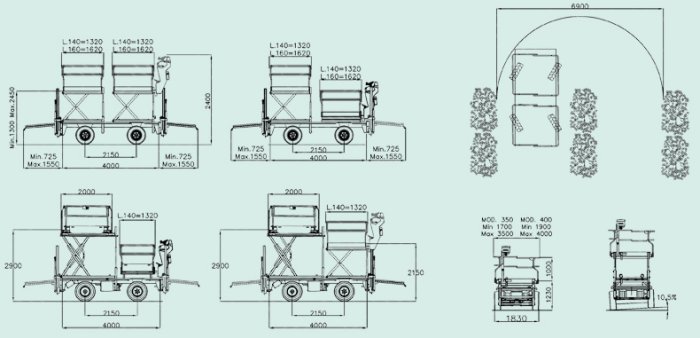

N. Blosi - Model Senior -Moving Machine

Diesel motor: Kohler LDW 1003 3cyl. Kohler LDW 1404 4cyl. Kubota D1105 3cyl. Kubota V1505 4cyl. Traction: Hydrostatic on 2 or 4 wheels. On request: hydraulic motor with variable cylinder capacity electrically controlled.

Electric Traction

- Electric Traction AC 48V power system complete with hours meter, battery charger, load indicator, traction control for up and down hill, automatic back up braking system. Electronic rectifier 220V.

Gears

- 2 gears + neutral in central position - electrical control from control panel.

Steering

- Whit hydraulic power steering on the front wheels.

- Indipendent steering on the rear wheels (only 4 wd).

- With 3 positions selector indipendent and/or combined on request.

Speed

- min 0 km/h max 13 km/h

Brakes

- Hydraulic on the rear wheels. Parking/negative brake on 4 wheels. On request hydraulic brakes on 4 wheels.

Platforms for fruit picking

- Nr. 1 front platform with hydraulic lifting.

- Nr. 1 rear platform with hydraulic lifting

Lifting forks

- Capacity max Kg. 500. Front and rear column shaped elevation max mm 1700.

- Rear column shaped elevation max mm 2550.

Front lift

- Column lift shaped elevation max mm 1700

- Capacity max Kg. 500.

Rear lift

- Column lift shaped elevation max mm 1700

- Column lift shaped elevation max mm 2550 (on request)

- Capacity max Kg. 500

Rolling for pallet boxes

- Rollers under rear platform are unavailable for platform M350.

Pruning system

- Air compressor C. 500/600 lt.

Total capacity of the machine: 13,200 lbs.

Benefits

- Increased productivity by about 150%

- The use of these platforms makes working in orchards less stressing and more productive.

- Compared with hand picking, the harvested fruits will have much less damages and bruises, which would mean much less fruit of second quality.

- The average operating life of our picking platforms is of at least 20 years, but we can count a large number of picking platforms still at work after 30 years.

- Normally a machine is paid back in 3 to 5 years, this counting not only the bare cost of the implement, but also all the servicing, fuel and labor. In other words, purchasing an N. Blosi can be a good investment.

Options

All our platforms, can be equipped with compressor for operating scissors and other pruning equipment, front / rear forklifts and rails for handling the bins, stop-and-go switch for facilitating the operations, work lights for a 24/24 use and many other options and accessories that would customize the machine and satisfy any need of the grower.

Uses

The self-propelled platforms of N. BLOSI were designed for trellis orchards of different sizes and types (e.g. apples, pears, peaches, plums, prunes, apricots, kiwi, etc.). Different models and outfits make the N. Blosi platforms very versatile to satisfy the needs of orchards all year around. In fact they can be used not only for harvesting, but also for pruning, thinning and maintenance works such, for example, placing hail nets.