- Home

- Companies

- Zhengzhou Huaqiang Heavy Industry ...

- Products

- organic fertilizer granualtor - organic ...

organic fertilizer granualtor - organic fertilizer granualtor

With the rapid development of organic fertilizer granulator, the small problems of organic fertilizer appeared. Attention is also paid to the matters needing attention when changing the oil of organic fertilizer granulator.

In recent years, it has developed rapidly in the domestic market, which is several times or even dozens of times that of the market and the previous years. With the rapid development of organic fertilizer granulator, the small problems of organic fertilizer appeared. Attention is also paid to the matters needing attention when changing the oil of organic fertilizer granulator. Some users of organic fertilizer pelletizer use waste oil plus half or 80% of the new oil to reduce the operating cost when they use organic fertilizer pelletizer. This method often loses a lot due to small reasons.

Because the waste oil in the organic fertilizer granulator is rich in many oxidation substances, rubber carbon particles and many iron scraps, it will greatly shorten the service life of the fresh oil, increase the speed of sports wear, not only can't play the role of oil change, but also cause mechanical problems such as burning tile and holding shaft. If the oil level exceeds the marking line, it will not only increase the consumption of oil, resulting in burning of oil and carbon deposition in the cylinder, but also increase the carbon particles in the oil, accelerate the wear of the cylinder and other parts, and shorten the service life. In addition, the remaining oil is drawn into the cylinder, which is easy to cause the appearance of speeding. Another situation is that in order to save maintenance costs, waste oil from the oil pan of the organic fertilizer pelletizer will be used in the gearbox, which will also be a small loss. Because there are many mechanical impurities in the transformed engine oil, it will accelerate the wearing speed of moving parts to participate in the gearbox.

In addition, the waste oil will make the gear oil thinner and the gear wear worse.

The waste oil can be used in the oil pan of air filter to save fresh oil. The viscosity of gasoline engine oil is small, which is suitable for light load operation. Diesel engine oil has high viscosity and is suitable for heavy load operation. Many of the organic fertilizer pelletizers work at high load in China, so pay attention to the oil change of the reducer of the organic fertilizer granulator.

organic fertilizer machine

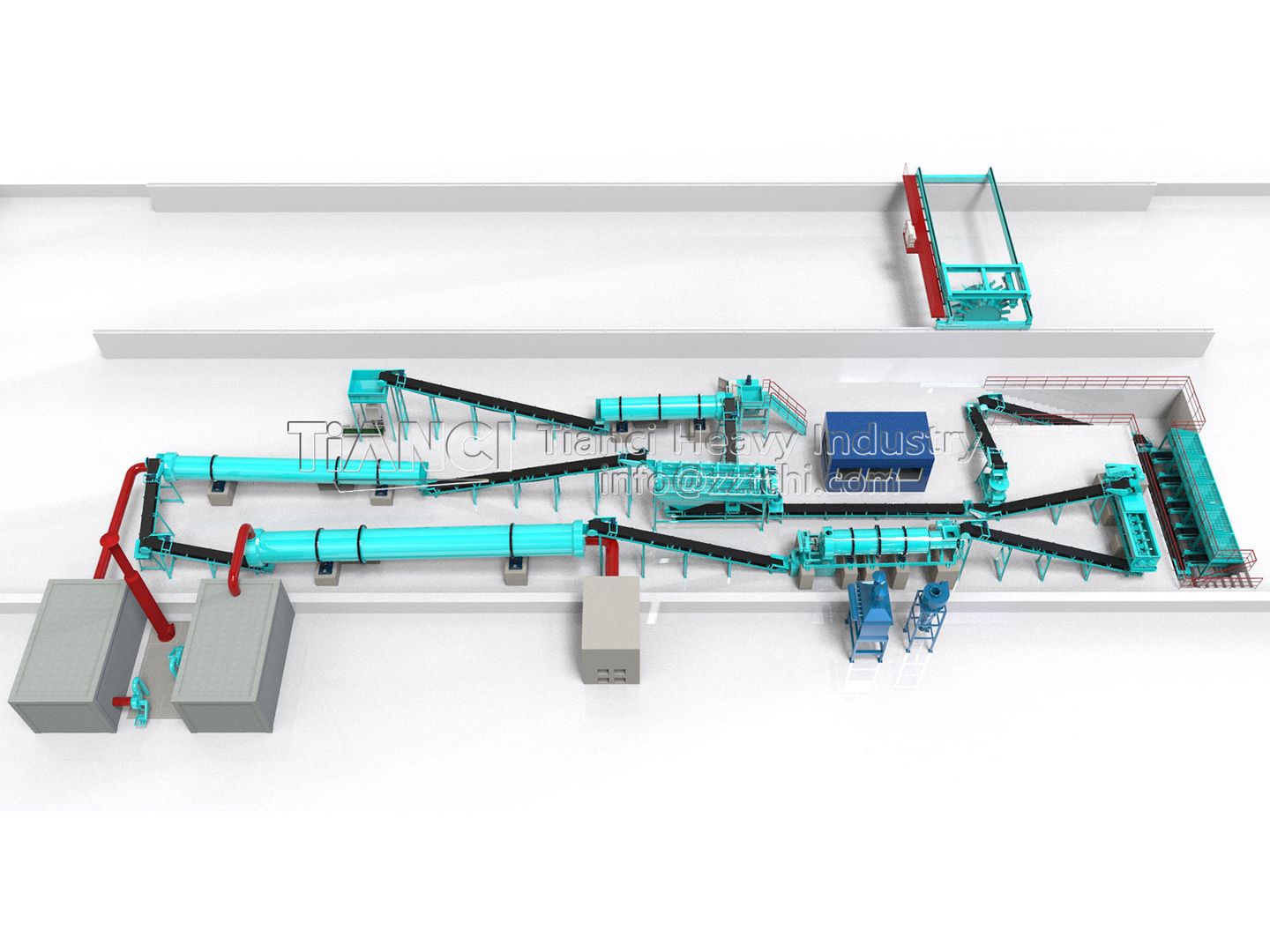

fertilizer production process

organic fertilizer granulator

compost windrow turner

In industrial production, the source of pollution is not only the pollution of the environment, but also the noise pollution. If the small grain drying organic fertilizer machine exceeds the range that the human body can bear, it will have a greater impact on the human body. How to reduce the noise in production?

In the dryer equipment, as an important part, the fan plays a huge role. The fan has been in continuous operation state in the fertilizer production process. Therefore, due to the excessive fatigue work of the fan, it will generate noise after a period of use. The fan will inevitably have some big and small problems in the long-term continuous overload work state, The generation of noise is obvious. How can we solve this problem?

As a large-scale mechanical equipment, the noise of the dryer will certainly bring interference to the surrounding people's lives. To solve the noise problem in time has become our primary key problem. Generally, we will increase the sealing degree or sound insulation cotton around the fan, but in the process of outdoor use, we should pay special attention to the temperature and ventilation of the fan Blind transformation can be carried out. Scientific and orderly process flow shall be carried out. The fan shall not be burned due to excessive temperature and improper heat dissipation caused by noise reduction. Generally, the fan can be divided into induced draft fan and blower. The role of induced draft fan is to quickly exhaust the exhaust gas generated in the drying process. The role of blower is to provide fresh air to the heat source combustion device of drying system Two kinds of fans play their own roles under different operation conditions of the dryer. The generation of general noise includes mechanical noise and aerodynamic noise. The most direct way to eliminate the noise is sound insulation. A sound insulation room is set outside the fan, so as to greatly reduce the noise transmission of the fan. The other way is to eliminate the noise generated by the fan of the dryer Install muffler in the place, so that the noise of the fan can be eliminated directly.