- Home

- Companies

- sí biotech

- Products

- síbiotech - Photobioreactor-based ...

síbiotech - Photobioreactor-based Microalgae Cultivation Technology for Omega-3 Extraction

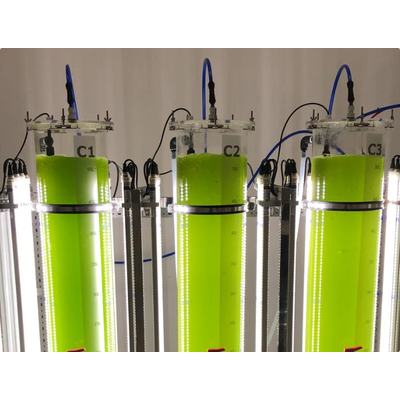

síbiotech has embarked on an advanced research project focusing on the cultivation of microalgae in photobioreactors, aimed at large-scale extraction of Omega-3 fatty acids. This initiative involves the use of a 0.15 m3 laboratory-scale bioreactor, with plans to scale up to pilot and industrial-scale systems reaching 30 m3, capable of yielding up to 600 kg of dry biomass monthly by the end of 2024. The automated photobioreactor ensures precise control over the cultivation cycle, enhancing repeatability and uniformity of biomass. The innovative process aligns with biotechnological techniques used in synthesizing active pharmaceutical ingredients. By utilizing microalgae cultivation, síbiotech offers a sustainable alternative to extracting valuable Omega-3s, typically sourced from fish, avoiding environmental damage and ensuring purity free from harmful compounds. This sustainable extraction uses supercritical fluid technology with CO2, enhancing the quality and environmental accountability of Omega-3, specifically eicosapentaenoic acid (EPA), which is vital due to its health benefits, including anti-inflammatory properties.

síbiotech’s research and development team has initiated the implementation of a research project and experimental development to establish cultivation processes for three different microalgae species in photobioreactors. The aim is to propagate them on a large scale and extract Omega-3 fatty acids.

síbiotech conducts microalgae cultivation in a laboratory-scale bioreactor system with a total volume of 0.15 m3.

However, by the end of 2024, the plan is to introduce pilot and industrial-scale photobioreactor systems with a total volume of up to 30 m3, producing up to 600 kg of dry biomass per month.

síbiotech’s photobioreactor system is fully automated, providing complete control over the cultivation cycle, ensuring repeatability and biomass uniformity for subsequent processing stages.

Microalgae Cultivation Process

The microalgae cultivation process occurs in two phases:

- In the first phase, conditions and parameters are selected to promote biomass growth in the shortest period.

- In the second phase, adjustments are made to the cultivation process, such as changes in light intensity, temperature, pH level, and other parameters, redirecting microalgae biochemical processes towards fatty acid biosynthesis.

Technology ensures sustainable extraction of fatty acids