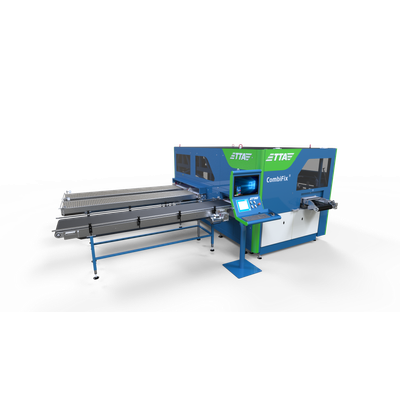

TTA-ISO CombiFix - Plant Tray Filling and Correction Machine

CombiFix is an advanced automated machine designed for efficiently correcting plant trays to achieve 100% occupancy with qualified plants. This system targets young plant trays, optimizing space and ensuring uniformity, which is crucial for automated transplanting processes. With its in-house imaging system, CombiFix evaluates each plant's optical appearance, identifying and removing empty plugs or substandard plants through a sophisticated blow-out mechanism. The machine incorporates a direct magnetic drive system for the plant gripper, ensuring rapid movement and precise positioning, thereby reducing maintenance over time. Additionally, the TTA-ISO's pusherpin technology allows even fragile plants with minimal root structures to be handled delicately. CombiFix supports sustainable operations by maximizing space efficiency and enhancing plant developmental consistency. Its compact size of 3.8 x 2.2 meters streamlines operations, supported by destacking units and discard rollers. Capable of processing between 12,000 to 20,000 plugs per hour, CombiFix sets a benchmark in automation for horticultural industries.

The CombiFix is the successor of the most successful gapping and correction machine for young plant trays ever.

The CombiFix is a fully automatic gapping-up machine that can fill trays to 100% after germination.

The machine presents the trays at the selection position. It then selects the incoming trays using the in-house imaging system based on the optical appearance of each individual plant. Empty plugs, as well as plants that are too small or of poor quality, are collected and discharged via the blow-out section. After the blow-out section, the trays are divided over two different chain conveyors. The CombiFix allocates one tray as a donor tray, which provides the plants. The other trays receive plants, thus being corrected to 100% full trays with qualified plants.

The head of the plant gripper moves between the donor and destination trays using a direct magnetic drive system. This allows it to accelerate very quickly and ensures highly accurate positioning of the plant grippers. This technique also reduces maintenance costs.

With the use of the TTA-ISO's pusherpin system, even fragile plants with an incomplete rooting system can be handled with almost no damage to the root plug. The advantage of repairing trays is an optimum use of available space, uniformity in plant material and plant development, and process optimization during automatic transplanting.

The market is asking for 100% filled young plant trays for use with automated transplanting. There’s no other machine on the market that offers the quality and speed of the CombiFix.

The CombiFix is designed as a small single frame (3,8 x 2,2 meters) in which all processes occur. Destacking units and discard rollers are available.

- Operators 1

- Plug diameter 9 - 30 mm

- Capacity per hour 12.000 - 20.000 plugs