- Home

- Companies

- Tensilkut Engineering Sieburg ...

- Products

- Model Tensilkut I - Precision Milling ...

Model Tensilkut I - Precision Milling Machine

Tensilkut is a precision milling machine designed specifically for machining flat tensile samples from metals and non-metallic materials. Tensilkut machined specimens are free of induced heat or cold working distortion, and are accurate to within +.0005”. A sample can be machined in a few minutes by lab technicians with no previous machining experience.

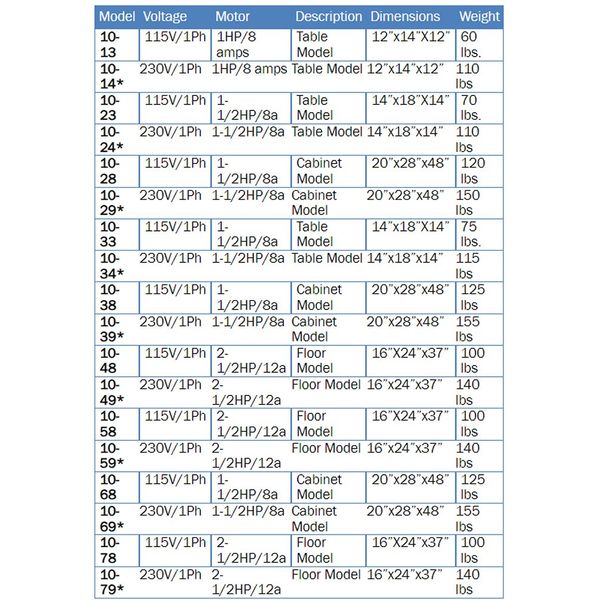

The Tensilkut I was designed for the specific purpose of preparing flat metal or non-metallic dogbone shaped test specimens. The compact size of the equipment permits it to be conveniently located in the laboratory. Small table top units or larger floor mounted models are available to accomodate any space and/or work volume requirements. Material thicknesses of up to 3/4”, depending upon the hardness and machineability of the material, can be cut on some Tensilkut I models. The specimens are accurate to within +.0005" when prepared on the Tensilkut machine with a Tensilbit and a standard or special master template manufactured by Tensilkut Engineering. Optional mist coolant and vacuum systems are available for the Tensilkut I.

The test strip is clamped in the template, which is manually moved across the Tensilkut table during the machining of the test specimen. The template’s upper guide bar rides along a guide sleeve, which is manually adjusted using the Tensilkut micrometer control. The specific depth of the individual machining cuts is dependent upon the machineability and gauge of the material being cut. Relatively deep cuts are used for roughing the sample to shape, whereas extremely light (.0005” to .001” deep) cuts comprise the finishing passes. When the sample is machined to its finished gauge width, the micrometer dial reaches a stop to automatically prevent further machining of the sample. The top template guide bar is undersized in relation to the finished test specimen, thereby preventing the template from making contact with the Tensilbit. The motor speed control, Tensilmist and Tensilvac can be installed on the Tensilkut I, if ordered with the machine.

The specific depth of individual machining cuts is dependent on the machineability and gauge of the metal or plastic being machined. A relatively deep cut can be used for roughing the sample to shape, whereas extremely light .0005" (.0125mm) cuts can be used for the finishing passes. The light cutting forces applied to the sample, due to the high RPM, allows the template to be easily moved with very little hand pressure. A sample of 1/4" (6.25mm) thick steel plate requires less than 16 ounces (450 grams) of force to achieve proper machining. When the sample has been cut to its finished gauge width, the micrometer dial reaches a stop to automatically prevent further machining of the sample. The top template guide bar is undersized in relation to the finished test specimen, thereby preventing the template from making contact with the Tensilbit.