Premier Tech

- Home

- Companies

- Premier Tech

- Products

- Premier Tech - Model CHRONOS OML Series ...

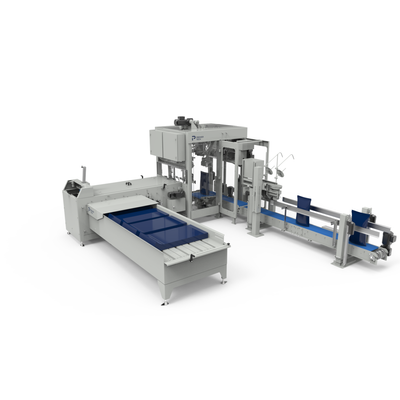

Premier Tech - Model CHRONOS OML Series -Fully Automatic Open-Mouth Bagging Machines

FromPremier Tech

Using unique advanced technologies, the OML Series automated bagging machines are designed to quickly fill pre-made open-mouth bags with 5 to 50 kg of any type of free-flowing or powdery products. They can handle bulk products like animal feed, sugar, rice, starch, fertilizers, seeds, and plastic pellets.

Most popular related searches

automatic bagging system

animal feed

animal feeding

feed hopper

animal production feed

rice seeding

rice seed

seeding

fertilizer

fertilizer pellet

The OML Series features three fully automatic models to fit your different packing, floor space, and speed requirements and budget. They come equipped with our gross or net weighing systems for optimal system performance.

- Speed: up to 25 bags per minute (1400 per hour)*

- Bulk materials: granules, powders, pellets, fibers, flakes, coarse aggregates

- Bag types: gusseted, gusseted flat bottom, and pillow

- Bag materials: paper, PE, laminated and non-laminated woven PP

- Bag weight: 5 to 50 kg (11 to 110 lb)

* Depending on the application, bag characteristics, and machine configuration

Versatile

- Adjustable spout opening to fit multiple bag sizes

- Can handle various product densities and weights as well as bag types and materials

Performant

- Controlled bag handling to prevent product contamination

- Detection system to confirm bag is correctly placed to avoid product spillage

- Minimized dust emission for cleaner operations

- Excellent machine accessibility, allowing cleaning and maintenance to be carried out quickly and effectively

Easy to use

- Total control of the bag during the entire cycle

- Programmable logic controller (PLC) with a user-friendly touchscreen operator interface for easy operation, troubleshooting, and error code reading

- Quick installation

- Stainless steel construction to withstand corrosive environment

- Double-walled, dust-tight spout

- Product de-aeration and posing

- Compatible with all common types of bag-closing and sealing devices

- Closed bag "push off" (top or bottom first) and bag turning devices (kicker or in-line turner)

- Tool-less changeover for multiple bag sizes

- Weighing system and feeding hopper adapted to your application

- Gusset retention and reforming

- Typical footprint from 4300 to 6400 mm L x 2720 to 3500 mm W (169 to 252" x 107 to 138")*

- Bag dimensions 250 to 700 mm W x 480 to 1100 mm L*

- Electrical requirements380/400V/3PH/50Hz (other voltages available)

- Air pressure requirements 5.5. to 6 bar

- Ambient temperature 5°C to 40°C (40°F to 105°F)

- * Depending on the model, please download the brochure for additional det