- Home

- Companies

- GreenPower

- Products

- GreenPower - Production of Pellets from ...

GreenPower - Production of Pellets from Sugarcane Bagasse

Sugarcane bagasse (bagasse) is a fibrous material that remains after crushing sugarcane; it is a valuable and inexpensive raw material available on many continents, which makes it an attractive alternative to wood. The use of bagasse helps reduce dependence on fossil fuels and wood resources, creating a sustainable and environmentally friendly energy system.

Chemical Composition of Bagasse (dry matter)

- Cellulose: 45–55%

- Hemicellulose: 20–25%

- Lignin: 18–24%

- Ash: 1–4%

- Waxes: <1%

Applications of Bagasse Pellets

As Fuel

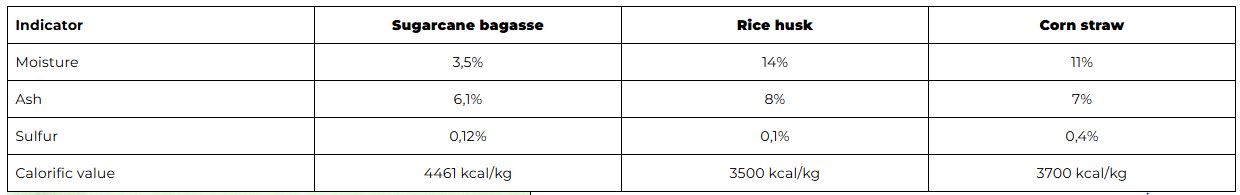

Pellets made from bagasse are considered one of the main energy sources in the biomass pellet market. Compared with other biomass raw materials, bagasse contains about 20% lignin, which facilitates pellet formation. At the same time, bagasse pellets have a higher calorific value — 4461 kcal/kg — and a relatively low ash content — less than 6.4% — compared with other biomass pellets.

To improve digestibility and nutritional value, sugarcane bagasse can be additionally processed: fermentation and/or steam treatment.

Bagasse Characteristics

- Crude ash: 4.76%

- NDF: 56.82%

- ADF: 54.36%

- Crude fiber: ≈ 44–46%

- Crude fat: 0.7%

- Crude protein: 1.5%

As a Carbon Source or Feed Additive

Bagasse pellets can be used as a raw material for producing charcoal or biochar. When bagasse pellets are pyrolyzed in BIO-Kiln units, a high-quality product suitable for industrial and agricultural use can be obtained (read more about Biochar characteristics), with lower ash content compared to natural fossil coal, which makes them an environmentally friendly and renewable certified product (read more) for the following industries:

- metallurgy (read more)

- construction (read more)

- electronics production (read more)

- fireworks production (read more)

- agriculture (read more)

Bagasse Pellet Production Process

Drying: raw sugarcane bagasse is dried to a moisture content of 15–18% in a rotary drum dryer. The unique design of the raw material feeding and dry bagasse discharge system, as well as the internal configuration of the dryer, prevents material hang-ups and ensures uniform bagasse moisture.

Note: It is optimal to use BIO-Kiln (active link) together with the pelletizing line, since excess heat from the pellet pyrolysis process can be efficiently applied for drum drying of the raw material.

Grinding: the dried fibers are milled to a particle size of 3–5 mm using a hammer mill specialized for this type of raw material, for subsequent pressing into pellets with a diameter of 6 or 8 mm.

Hammer crusher

Metal removal from the raw material: three powerful magnetic separators are installed in the bagasse grinding system and in the bagasse pelletizing system. The magnetic separators protect the equipment from damage and ensure consistently high product quality. Three powerful magnetic separators are installed in the bagasse grinding system and in the bagasse pelletizing system.

Pelletizing: the raw material silo, screw feeder and force feeder are designed with anti-blocking protection; the cooling system installed on the pellet mill allows the temperature in the pelletizing chamber to be reduced and dust to be removed from the chamber; the specially designed ring die increases pellet forming efficiency; the main shaft and roller shafts are forged to form an integrated structure, which prevents roller vibration and extends the service life of the ring die and roller bearings.

Cooling and screening of pellets: the pellets coming from the pelletizer are cooled in a counterflow cooler, where the pellet temperature can be reduced by 30–40 °C; dust and unformed particles are separated using a vibrating or rotary screener.

Pellet packaging: both bulk container packaging and packaging in 15–50 kg bags are available. A fully automatic packaging system is optionally available.

A comprehensive system for processing sugarcane bagasse into pellets ensures the production of high-quality biofuel and feed additives, and also serves as a raw material for the production of high-quality CHARCOAL and BIOCHAR.