Strahl srl

Strahl - Model AR Series -Recirculating Batch Grain Dryers

FromStrahl srl

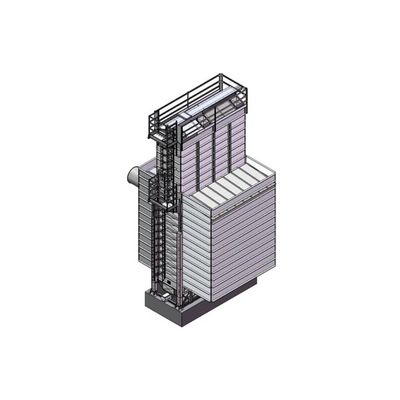

The AR series takes advantage of recirculating batch drying. This is a special technology which is particularly suitable for those who need to dry small quantities of product and/or with high product rotation. These dryers are particularly effective for drying rice.

Most popular related searches

Construction features of the AR series

- The recirculating batch grain dryers manufactured by Strahl are made of galvanised sheet metal panels that make them exceptionally robust. They have an upper hopper with braided reinforcement pipes and Aluzinc coating, which is the same material used for the air distribution ducts.

- The whole machine is built with panels having flaps on the outside and with a final drip tray, to avoid the dangerous build-up of dust inside the chamber. The extractors have a special design and a high ratio between the diameter of the impeller and that of the fan which allows noise to be reduced. Noise reduction is also guaranteed by the layer of stone wool covering the internal sides of the extractors.

- The AR Series is manufactured with two versions: one with linear burners, the other with traditional burners. Finally, the discharge device allows large quantities of product to descend in a very short time, avoids pollution phenomena when passing from one cereal to another, and excludes the risk of jamming even in the presence of foreign bodies.

Operation of the recirculating batch grain dryers

- In the AR series dryers, after having completely filled the machine, the product recirculates inside the dryer itself thanks to a bucket elevator placed outside; in this way it alternately crosses the drying area and the upper tempering hopper.

- In the drying phase the product descends by gravity through a series of staggered ducts; these cause the product to fall in a zigzag movement and to be continuously mixed together. The shape of this path allows the product to descend evenly along the entire section of the column, thus avoiding parts of the product falling faster than others. The time spent inside the hopper allows the product to become uniform and the internal layers of moisture to move outwards; the result is a slow and uniform drying process that makes the dryers particularly suitable for rice.

- The exchange system between the air and the product in recirculating batch grain dryers is a mixed flow system. In this process all the product is crossed by both a concurrent and counter-current air flow.

How AR grain dryers can reduce emissions

- Strahl cares for environmental sustainability and all our machines are built with measures aimed at reducing emissions into the atmosphere. First of all, when the pressure in the dryer is reduced, the saturated air is collected by the upper extractors and, therefore, there are no emissions in the workplace.

- Dust is emitted when the dryer is operating due to the passage of the product by the air that removes the lighter parts. Strahl has therefore implemented special important measures to reduce product handling and air speed while the product is in circulation. One of them is the presence of an extraction device that allows large quantities of product to be discharged in a very short time.

- A significant quantity of dust is emitted only during the extraction, which lasts about 20-40 seconds every hour; to further reduce the emission, the air flow is interrupted during the movement of the product.